Joint project PriFUSIO explores technological paths to commercialize inertial fusion / 2024

New foundation for laser fusion research

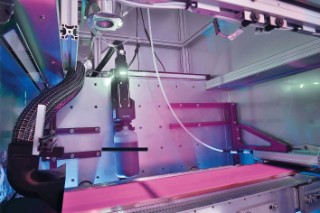

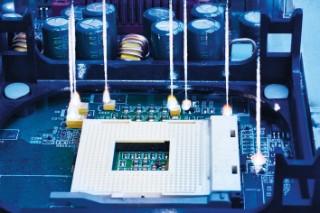

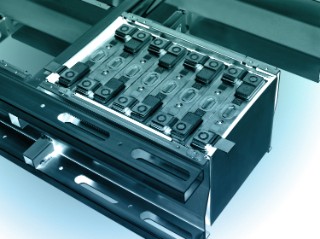

Boost for Inertial Fusion Energy (IFE) in Germany: The PriFUSIO research project aims to systematically develop key technologies for climate-neutral fusion power plants of the future. The consortium, led by the ILT in Aachen, brings together fusion start-ups, medium-sized companies, large corporations, the Laser Zentrum Hannover, and the Fraunhofer Institutes IOF in Jena and ILT in Aachen, creating a diverse collaboration of industry and public research institutions. The project will focus on principles for targeted component development and explore practical photonic approaches for the commercial utilization of laser-driven IFE. The Federal Ministry of Education and Research has allocated 18 million euros for the project over the next three years.

more info Fraunhofer Institute for Laser Technology ILT

Fraunhofer Institute for Laser Technology ILT