Cutting

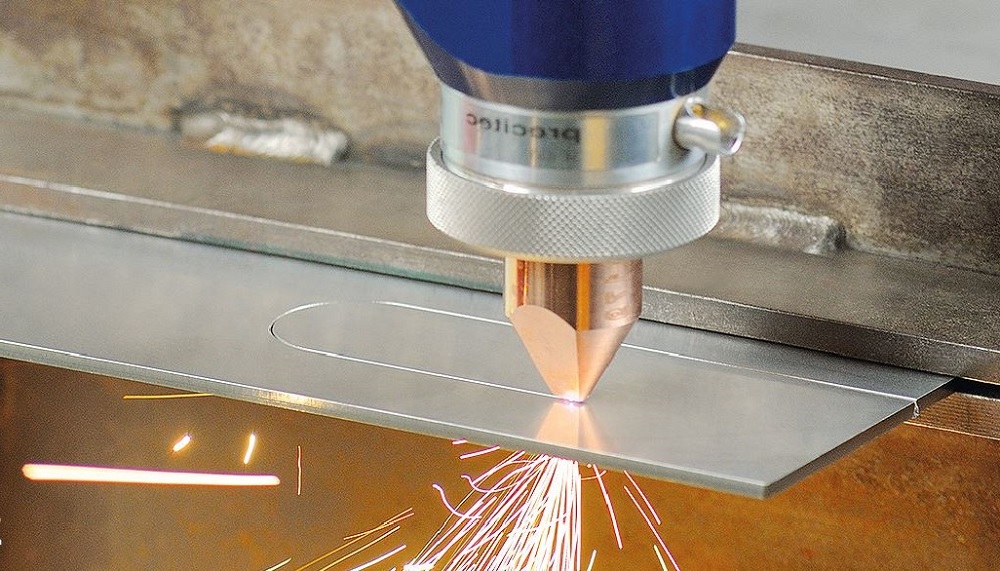

Fraunhofer ILT provides its customers with laser-based solutions for new or technically and economically optimized processes in cutting technology and supports them from the initial feasibility study to industrial implementation. Cutting quality, processing speed and robustness of the processes are the most important target variables, in addition to economic efficiency.

The institute develops processes and process-specific components such as optical systems, cutting nozzles and control systems for laser cutting. The basis for this is, among other things, diagnostic procedures and simulation tools, with which high-quality cuts can be realized through targeted beam shaping and adapted control systems. In addition to high-performance processes such as high-speed cutting and thick sheet cutting, the institute focuses on integrated applications that combine cutting, welding and additive powder processes. One emphasis of its research and development is on lightweight construction applications based on function-integrated components. In this area, for example, Fraunhofer ILT is continuing to develop laser cutting of fiber composites.

The use of ultrafast laser radiation enables high-precision and almost material-independent material processing. Since this radiation introduces such low heat input into materials, it can generate structure sizes down to the sub-micrometer range. Among other things, it is used for drilling and cutting precision components, for surface structuring or for selective thin-film ablation. Economical cutting and structuring processes are used, for example, for new hydrogen technologies, such as the efficient production of bipolar plates for fuel cells.

Fraunhofer Institute for Laser Technology ILT

Fraunhofer Institute for Laser Technology ILT