Our range of services

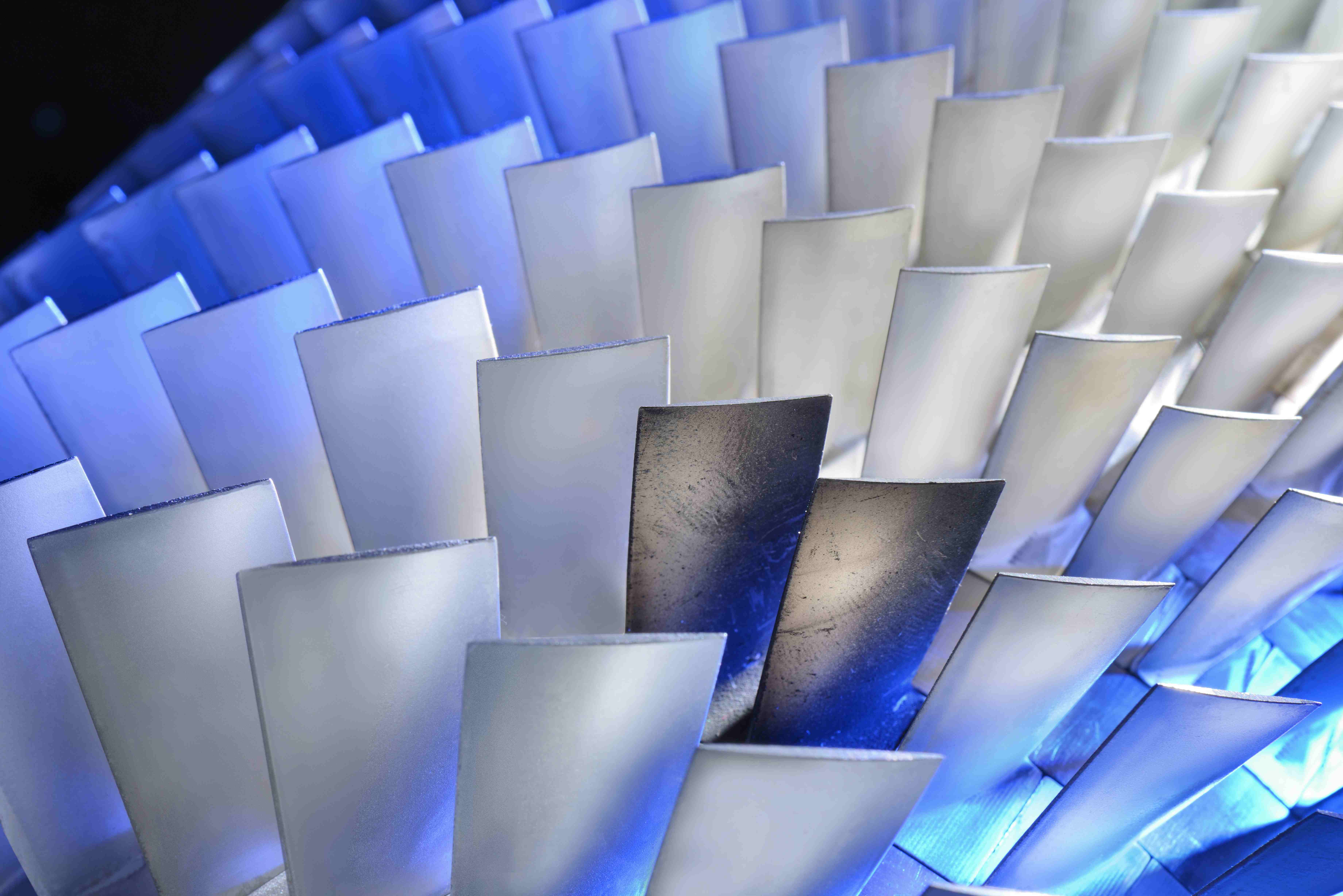

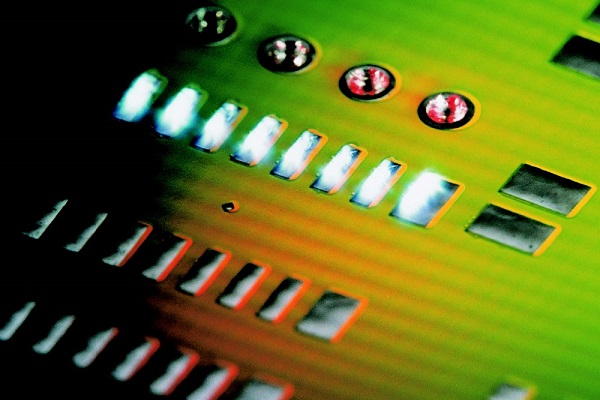

Tailor-made laser processes are suitable for cleaning and stripping various kinds of components. Such processes are based on locally limited interaction of pulsed or continuous laser radiation with surface layers. A chemical reaction or thermal decomposition takes place, for example via evaporation or sublimation, depending on the laser wavelength, intensity and interaction time of the radiation with the surface layer and the material properties. With these processes, components can be cleaned on both a large-scale and locally down to the micrometer range, whereby oxide layers or particulate and filmic contaminants such as fats or oils are efficiently removed. Fraunhofer ILT develops efficient, laser-based cleaning processes with high spatial resolution for applications in various industrial sectors.

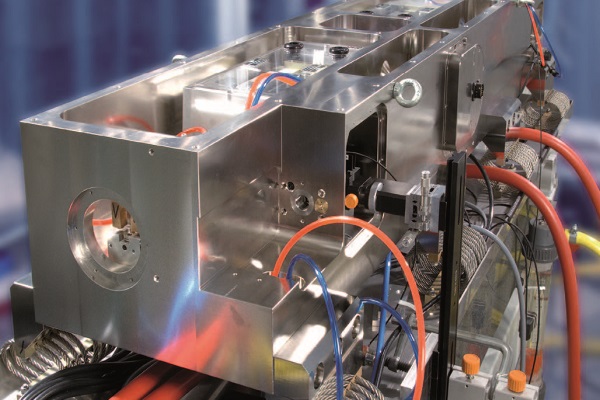

Cleaning and stripping can be used in pre-treatment for joining processes – such as brazing, welding or gluing – to activate plastic surfaces or to protect of steel structures against corrosion. Furthermore, manually guided machining heads can be used to clean aircraft components or rail heads flexibly, with fiber-coupled laser sources used in pulsed operation.

The services offered range from feasibility studies, the development and implementation of application-specific cleaning processes and corresponding system technology, integration into existing industrial processes and individual consultation.

Fraunhofer Institute for Laser Technology ILT

Fraunhofer Institute for Laser Technology ILT