Hamburg / October 21, 2025 - October 23, 2025

Hydrogen Technology Expo Europe 2025

Hydrogen Technology Expo Europe is the must-attend conference and exhibition that is exclusively dedicated to discussing advanced technologies for the hydrogen and fuel cell industry. The event will bring together the entire hydrogen value chain to focus on developing solutions and innovations for low-carbon hydrogen production, efficient storage and distribution as well as applications in a variety of stationary and mobile applications

We look forward to presenting a wide range of exhibits from our hydrogen application field at the Hydrogen Technology Expo Europe in Hamburg in Hall B4 at Booth 4F13.

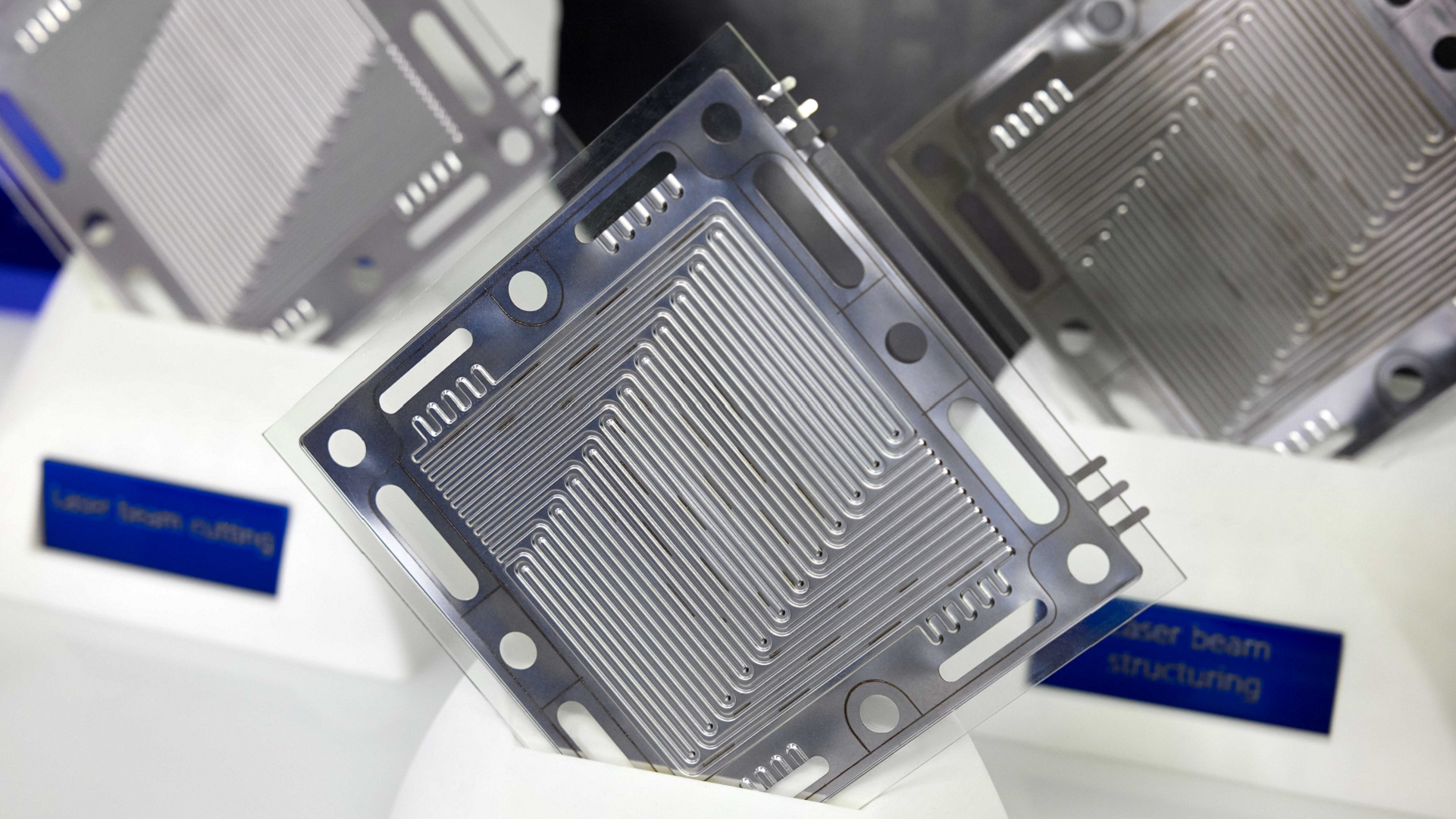

Bipolar plates are key components of fuel cells, ensuring gas distribution, cooling, and electrical contact between the electrodes. The Fraunhofer Institute for Laser Technology ILT develops laser-based processes for the precise and efficient manufacturing of bipolar plates. The goal is to enhance the performance, durability, and cost-effectiveness of fuel cells through innovative laser technologies.

With dual-beam laser welding, the production speed of metallic bipolar plates can be increased by up to 50 percent, while simultaneously improving weld quality and process stability. In addition, Extreme High-Speed Laser Material Deposition (EHLA) extends the lifetime of forming tools by applying wear-resistant coatings and enables cost-effective repair.

The ILT’s laser-based coating process creates conductive and corrosion-resistant protective layers without the need for complex vacuum systems. A sprayed-on precursor layer is functionalized by laser radiation – an ideal solution for continuous, energy-saving production lines.

During laser structuring, microstructures are generated that optimize gas flow, reduce corrosion, and minimize electrical resistance. State-of-the-art femtosecond laser systems enable large-area, high-precision processing of both metallic and composite plates.

Through these complementary technologies, Fraunhofer ILT offers a comprehensive portfolio for the laser-based structuring, coating, and joining of bipolar plates – making an essential contribution to the industrial implementation of hydrogen technologies.

With rising demand for fuel cells, efficient production processes are becoming increasingly important. A key bottleneck is drying the wet-applied electrode layers in the membrane electrode assembly (MEA) of PEM fuel cells. Conventional convection ovens require substantial energy and floor space

Fraunhofer ILT has developed a laser-based drying technology that revolutionizes this step. Targeted laser irradiation of the electrodes cuts drying time from several minutes to just a few seconds, enabling significantly higher production speeds, especially in roll-to-roll processes.

At the same time, the method substantially lowers energy consumption and reduces the footprint on the factory floor. Laser-assisted drying thus offers a compact, flexible, and sustainable alternative to conventional drying methods, an important step toward cost-effective volume production of fuel cells.