At the Fraunhofer ILT Battery Lab, researchers focus on optimizing key parameters of batteries, such as capacity, energy density, performance, weight, charging time, charging cycles, chemical composition, and production parameters. The aim is to develop powerful, safe, and cost-effective batteries that meet the specific requirements of various areas of application.

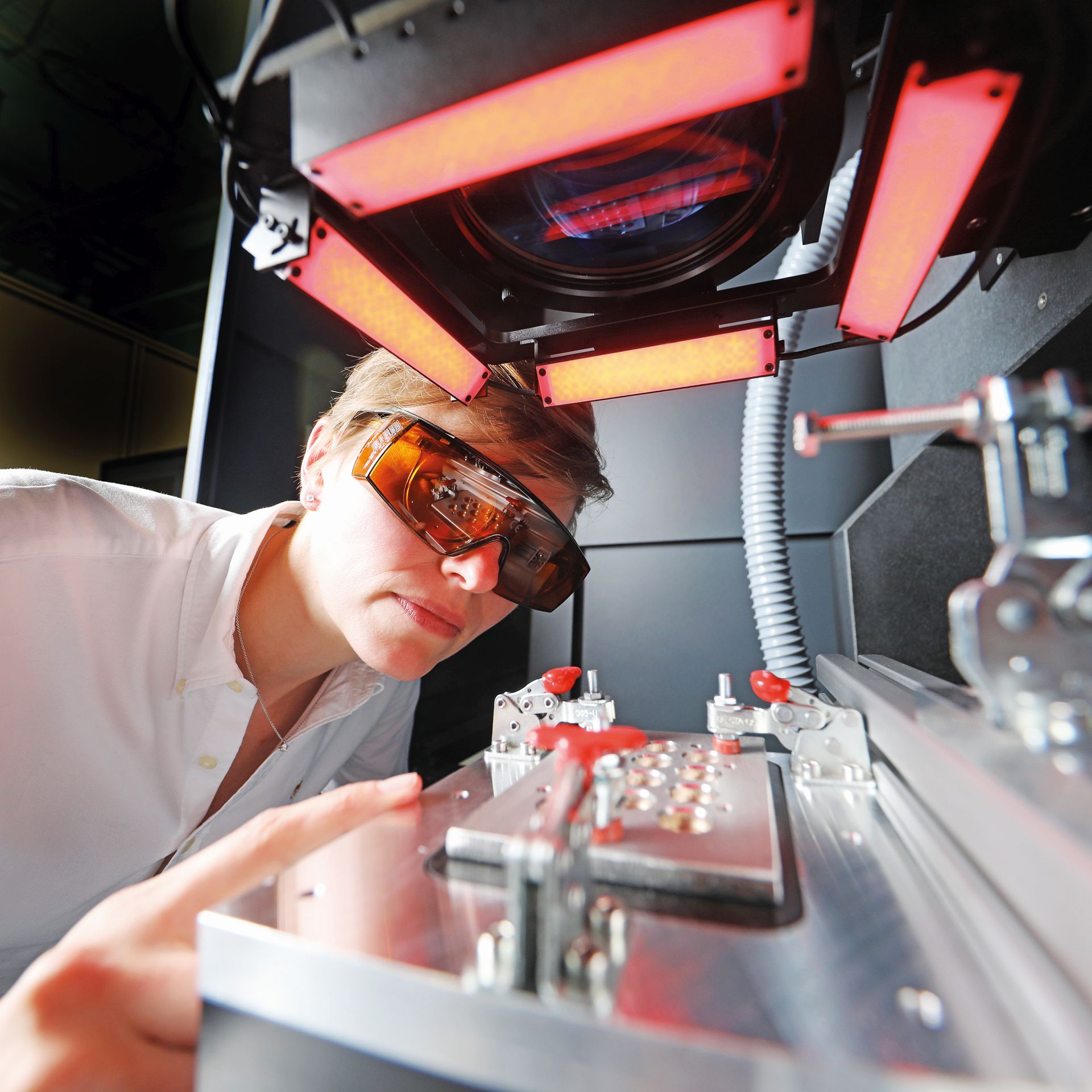

Covering an area of almost 140 square meters, scientists have access to state-of-the-art technologies and a wide range of equipment for laser-based battery production. They are researching new materials and processes for both conventional lithium-ion batteries with liquid electrolytes and future solid-state batteries. Electrical and mechanical test benches enable them to directly evaluate and further optimize the laser processes.

The Battery Lab is equipped with an argon-powered glove box system that integrates vacuum-based PVD coating technology and a high-temperature furnace. This allows researchers to coat air-sensitive solid-state cell materials and then install them in test cells.

Additionally, they are investigating the possible applications of laser technology for cutting and welding battery components in the Battery Lab. The use of UKP lasers enables precise and damage-free processing of electrode foils. The Fraunhofer team connects battery cells to battery modules and modules to battery packs in order to make conventional production processes more efficient.

Fraunhofer Institute for Laser Technology ILT

Fraunhofer Institute for Laser Technology ILT