Surface Technology

In “Surface Technology,” Fraunhofer ILT focuses on developing laser-based technologies for the efficient processing, functionalization and finishing of surfaces.

Thin films are used for electronic applications, for wear and corrosion protection as well as for optical and structural applications. Since lasers have specific advantages – they are locally selective, have inline capability as well as placing a low thermal load of the workpieces – they open up many new possibilities in designing new production processes and components in which functionalities can be integrated.

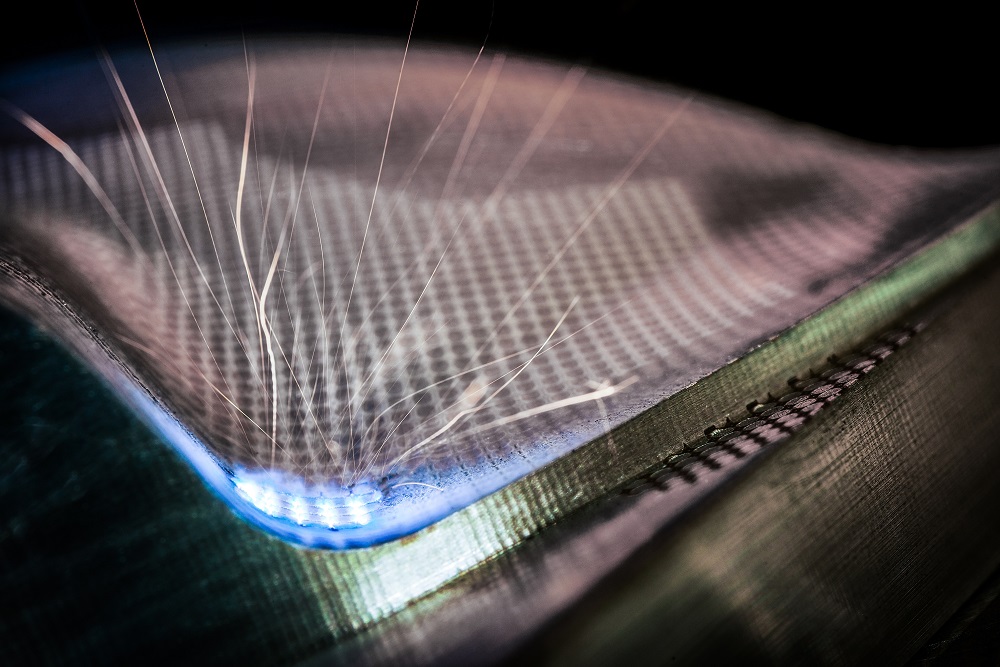

Component condition data, such as thermal and mechanical loads, can be collected by special sensors and form a basis for predictive maintenance, big data and AI approaches in production. Fraunhofer ILT combines various manufacturing methods, for example, to equip printed lightweight components with appropriate sensors. By combining Laser Powder Bed Fusion with digital printing and laser post-treatment processes, the institute is paving the way for the production of “sensing” components.

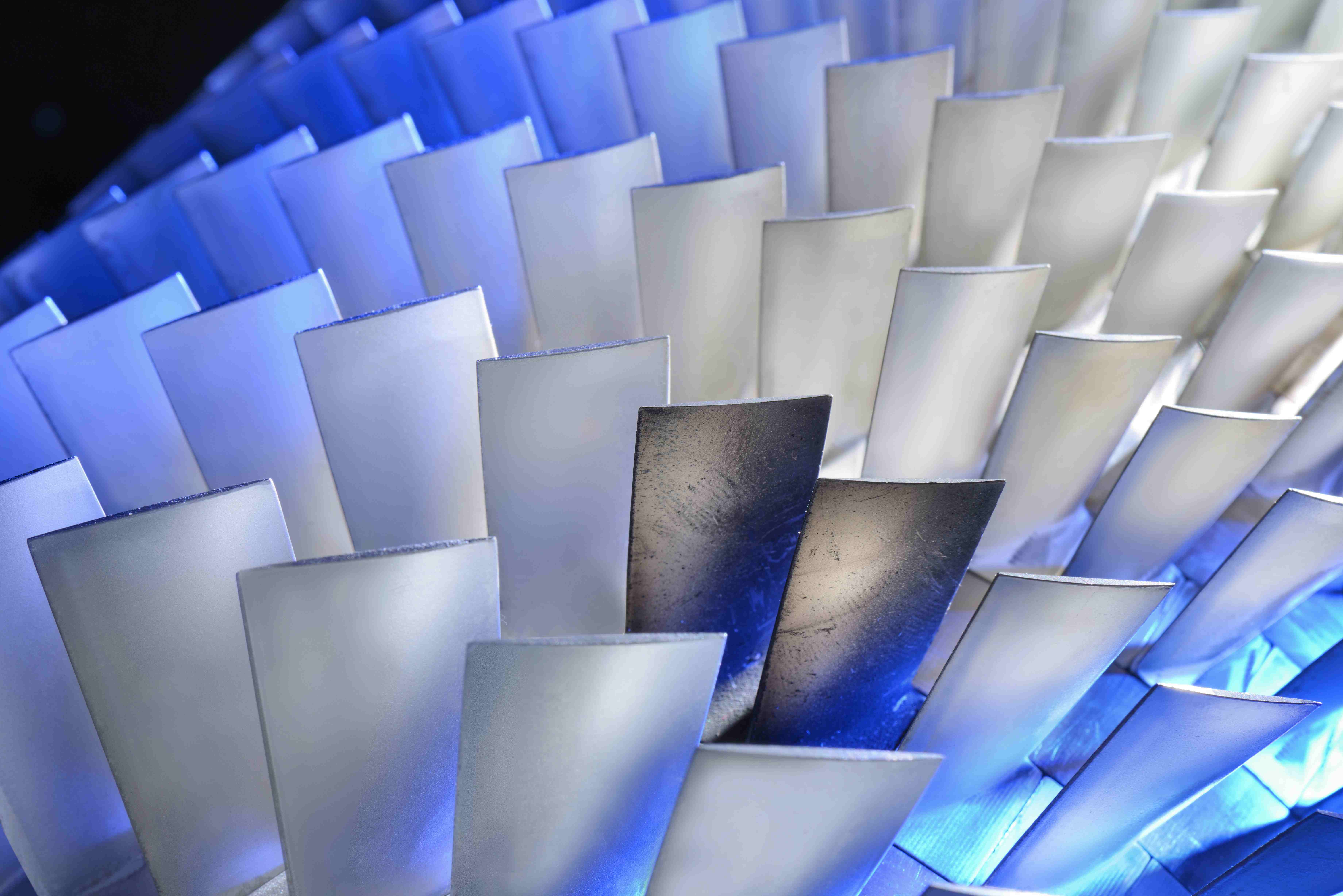

Thanks to their functionality, structured surfaces contribute, for example, to minimizing friction in combustion engines, to increasing efficiency in lighting systems or to improving the activation of chemical processes in fuel cells. Surface properties also play an important role as a quality feature of products.

Fraunhofer Institute for Laser Technology ILT

Fraunhofer Institute for Laser Technology ILT