Joining

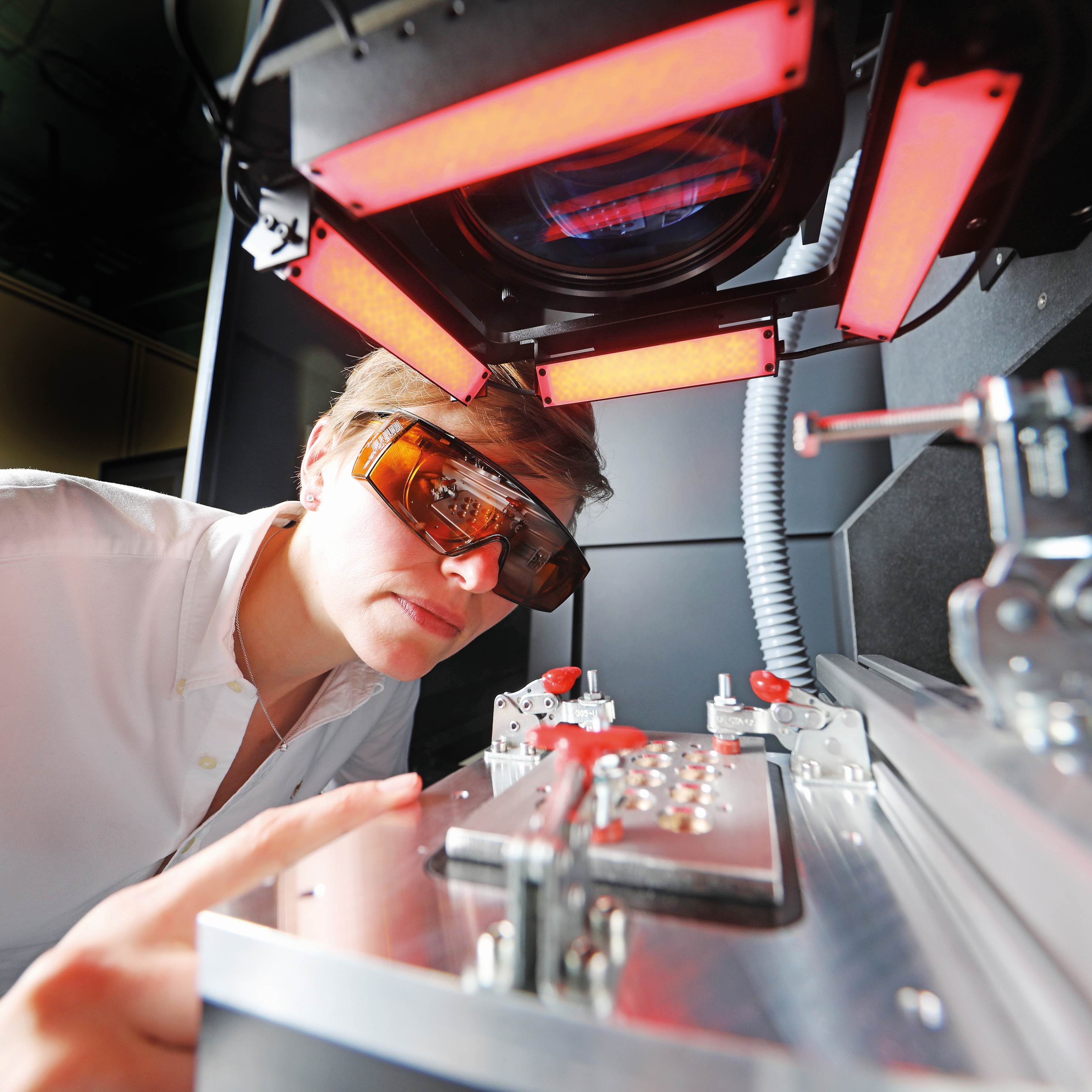

Fraunhofer ILT develops laser beam sources and laser-based joining processes for numerous applications in micro and macro technology. It focuses on extending current process limits, for example, to increase processing speed and precision and to improve weld seam quality. By implementing specific optical systems, nozzles, processing heads and control systems, the institute puts efficient and reliable processes for joining identical or dissimilar materials into practice.

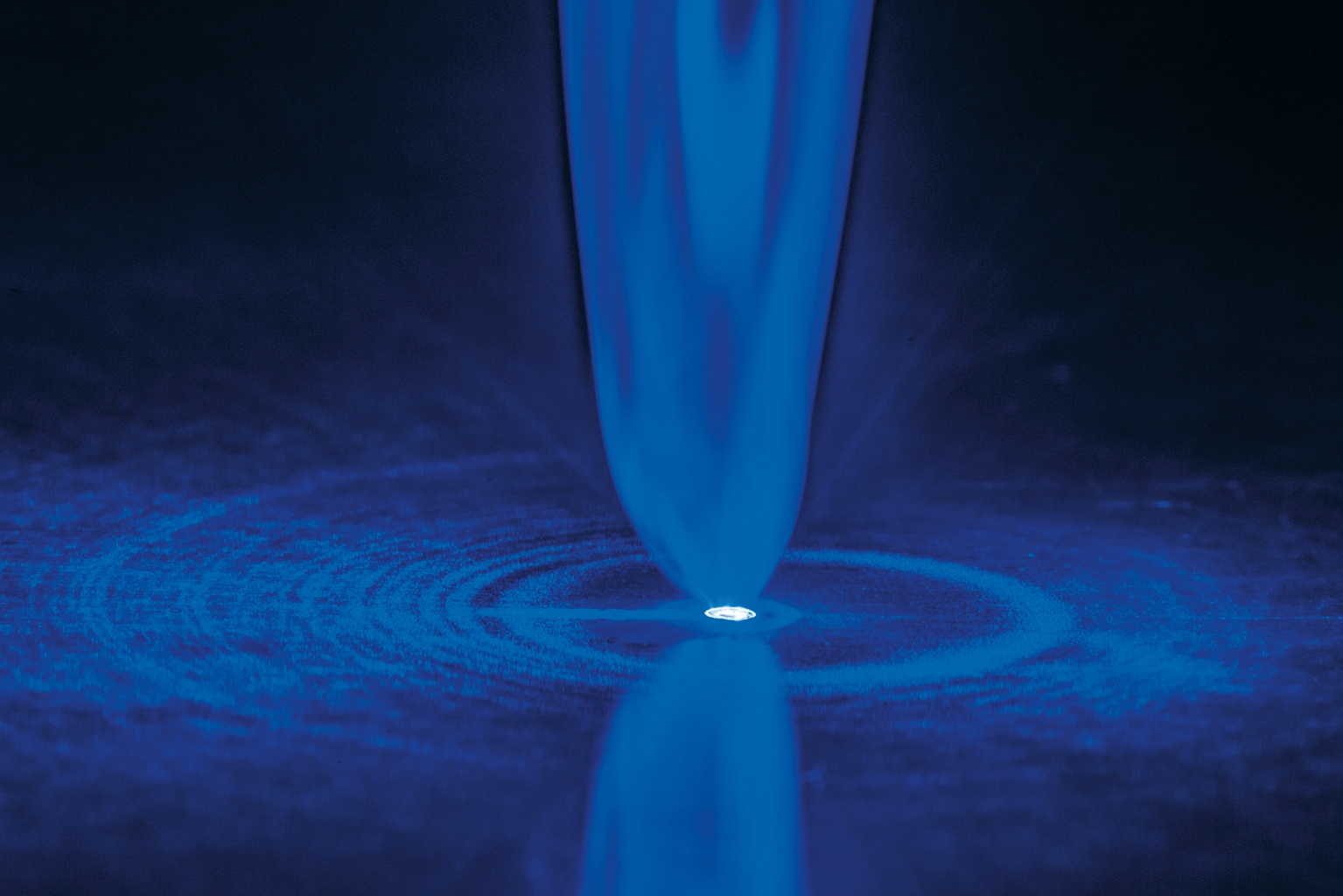

Metals and plastics as well as material combinations such as silicon-glass or plastic-metal can be joined reliably with laser radiation. At the same time, laser processes are suitable for materials that are difficult to process, such as ultra-high-strength steels, high-strength aluminum alloys or (fiber) composite materials.

High accuracies and qualities in weld seams can be achieved through targeted beam shaping and guidance as well as application-specific controls. The institute is continuously developing and adapting processes such as precision welding of metals, plastic welding or glass and ceramic processing for industrial applications. It also focuses its research and development on integrated applications that combine welding, cutting and additive powder processes.

Fraunhofer Institute for Laser Technology ILT

Fraunhofer Institute for Laser Technology ILT