Yesterday ILT, today IoL

This simple denominator sums up the latest commitment of Professor Reinhart Poprawe, director of the Fraunhofer ILT until 2019. Five years ago, Poprawe filed a patent application as co-inventor for the laser-based production of plastic lenses (intraocular lenses, or IoL). On this basis, the company AIXLens GmbH was founded in Alsdorf near Aachen, Germany. It manufactures individually adapted lenses from plastic in a fully digitalized and completely laser-based process, independent of the material used. Patients receive their personal lenses just-in-time without storage directly from production in a batch size of one. And the lenses correct all refractive errors specific to the patient.

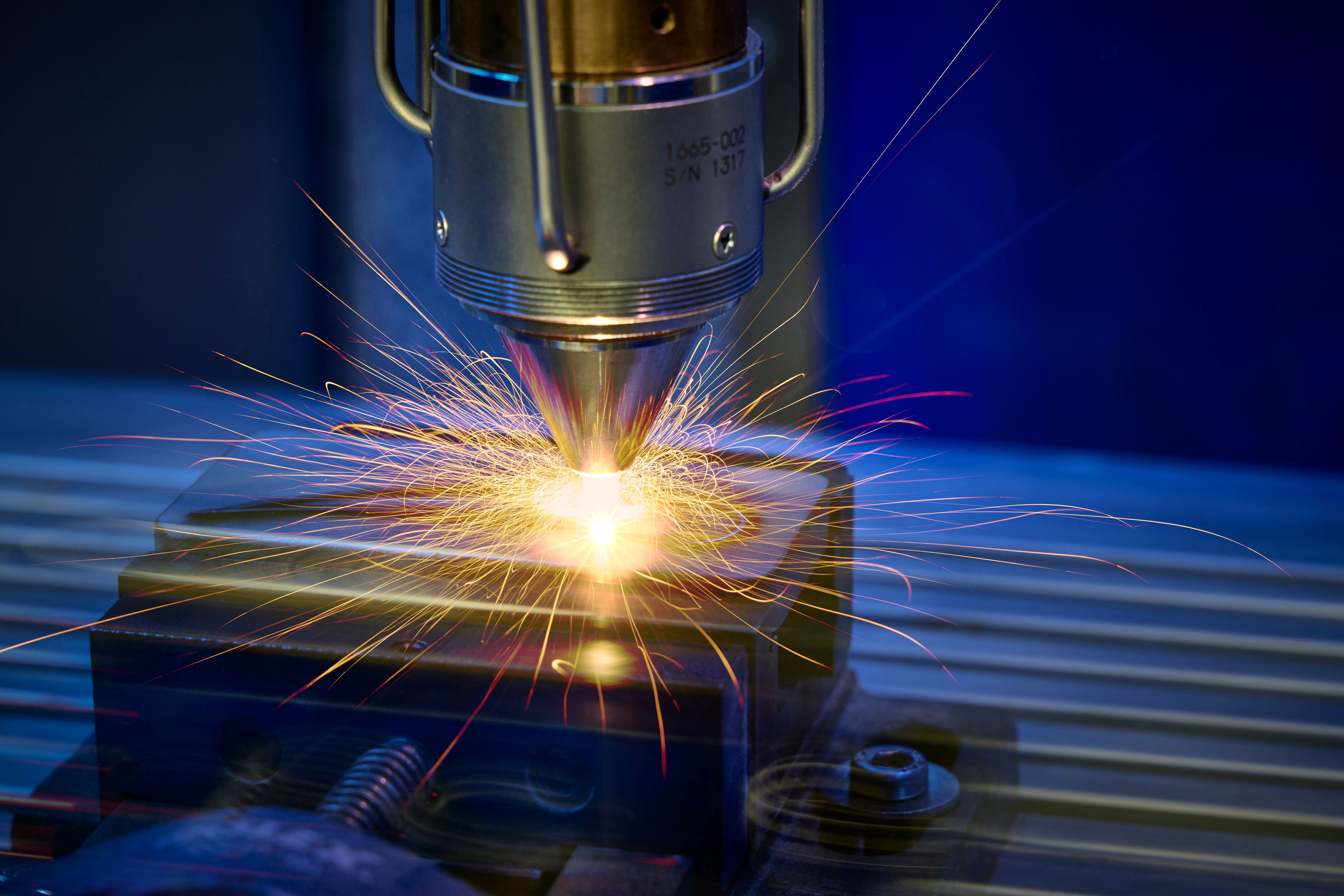

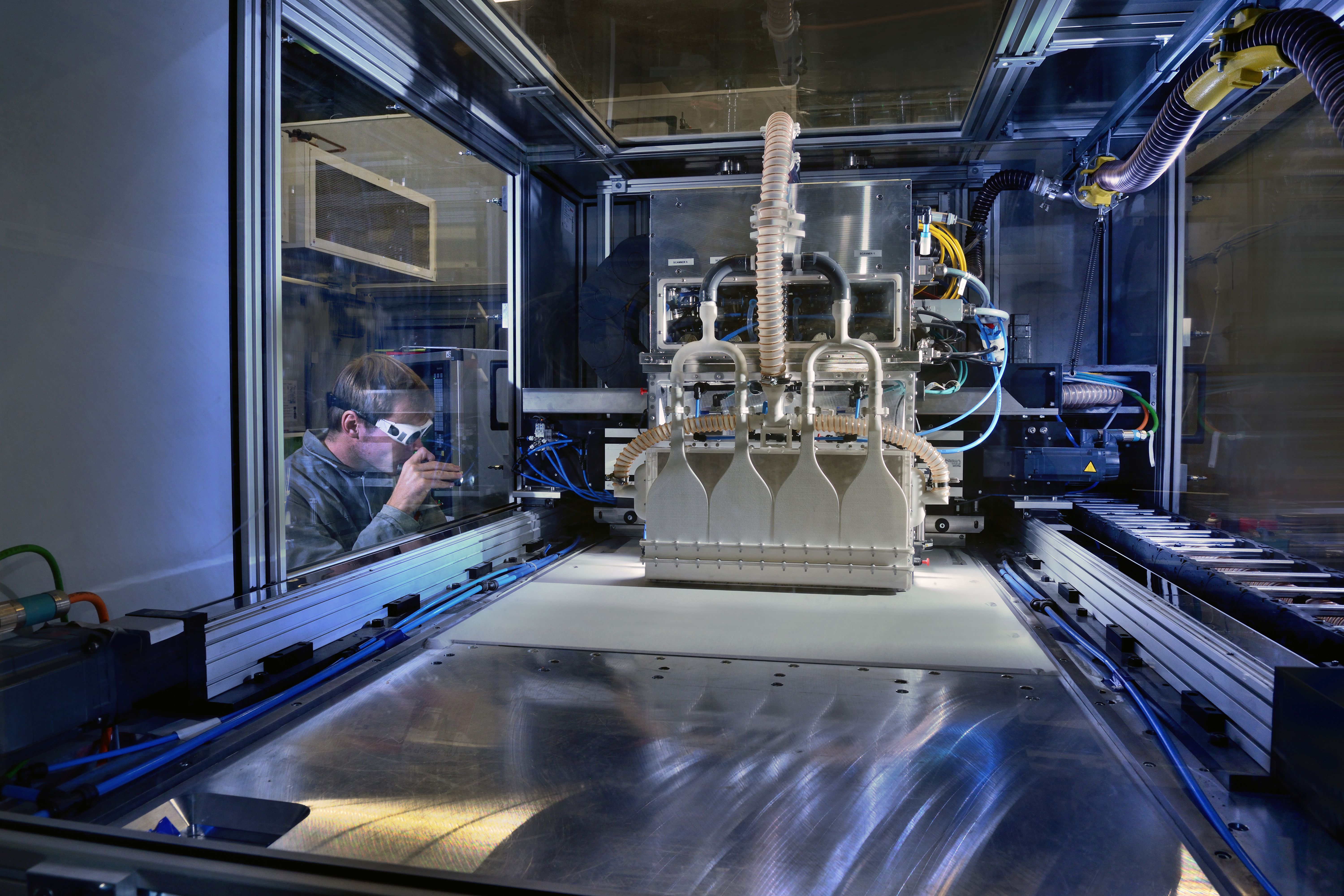

This is where the strength of the laser comes into play: the precise, productive and sustainable production of components in high complexity and in small quantities. After measuring the eye and generating the data, the lens is created within a few minutes: An ultrashort pulse (USP) laser creates the lens by ablation, which is then polished with a CW laser. Then a USP laser cuts the so-called haptics to attach the lens. “It's a completely digitally controlled process chain where nothing is touched,” Poprawe explained. “When someone orders the lens, the delivery date now basically depends only on the shipping time.”

Production without employees

The business model is also unusual: There are no employees at AIXLens, because the development of the process and the installation of a demonstration line are done on behalf of Fraunhofer ILT. The key data are impressive: Lenses with a surface roughness in the range of single nanometers and very precisely maintained diopter values are produced in a batch size of one.

However, AIXLens had to solve a special technical problem in the nationally and internationally patented process: Tiny polymer chains form during laser polishing of thermosets, and owing to them, the lenses initially failed the biocompatibility test. The remedy was to irradiate the laser-polished lenses with electrons, which reconnected the broken molecular chains. Since then, the lenses have also passed the biocompatibility test.

The effort was worth it because the resulting new form of IoL production opens up a wealth of completely new possibilities. “In conventional production, manufacturers have to keep 400 different sizes of lenses in stock at all times, which they have to constantly replenish because of the products' expiration dates,” Poprawe explained. “That's all eliminated with us.”

While IoL lenses are suitable for people with cataracts, patients suffering from glaucoma due to ocular hypertension need micro-stents that drain the aqueous humor into the natural outflow channel. These components, which are only 300 µm thick, can also be produced with the laser: Laser etching of glass (selective laser-induced etching, or SLE) is used at aixtent GmbH, also based in Alsdorf. The former Fraunhofer ILT boss did not reveal details, but laser etching is also likely to be integrated into a process which, like IoL production, is agile and fully digitalized in close cooperation with Fraunhofer ILT.

The physicist did not specifically address one factor that is crucial for success: the price. Because series production has not yet started, entrepreneur and co-inventor Poprawe does not want to give exact figures yet, but he is optimistic in view of the previous complex manufacturing process and the high expense for logistics and storage: “I am sure that our lenses will be significantly cheaper. In the entire process, we benefit extremely from the structure on the RWTH Aachen campus; without it, none of this would be possible.”

Fraunhofer Institute for Laser Technology ILT

Fraunhofer Institute for Laser Technology ILT