Diamonds have some striking properties: for example, their refractive index is 2.4, which is extremely high and allows much thinner optics to be made. Their thermal conductivity is 2000 W/m*K and is, therefore, more than 1400 times higher than that of optical glass. Along with their high damage threshold, these properties make diamonds highly interesting for high-power optics.

To date, polycrystalline diamond substrates have only been used as windows for CO2 lasers. Due to impurities and imperfections, they absorb and scatter laser radiation at emission wavelengths about 1 μm, making them unsuitable for fiber lasers. Although single crystal diamonds do not have this problem, they are more difficult to manufacture.

The Fraunhofer Institute for Applied Solid State Physics IAF in Freiburg has been researching the production of monocrystalline diamonds for years. The CVD reactors developed at the IAF have stable plasma conditions and make substrates of up to several millimeters thick possible.

A maximum of 60 diamonds can be produced simultaneously. At build rates of up to 30 μm per hour, the reactors can produce optics with an aperture of approx. 10 mm.

90% Weight Reduction for Laser Heads with Diamond Optics

Lenses from the synthetic single crystal diamonds from Freiburg show low absorption and also low birefringence. Currently, a few specimens have been provided with antireflection coatings and incorporated into a fiber-laser cutting head.

Martin Traub from the Fraunhofer Institute for Laser Technology ILT in Aachen says, »We have optimized a complete laser optical system for the diamond lenses for the first time. Thanks to this, the cutting head is more than 90 percent lighter«.

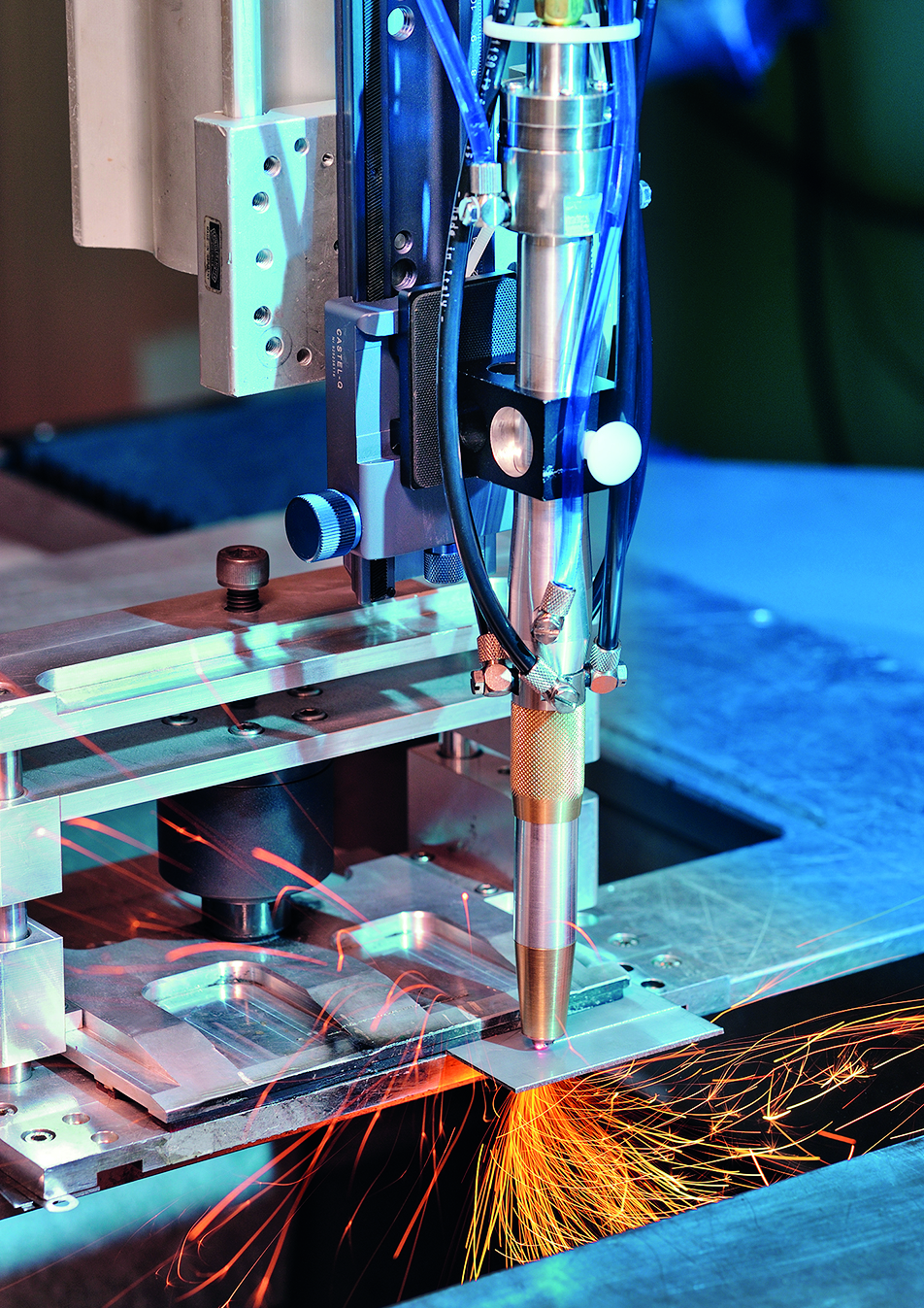

The lenses with 7 mm diameter had previously passed tests with 2 kW laser power without problems. Now, the partners have built a system for cutting tests with a 1 kW fiber laser. Integrated in the cutting head are water cooling and the shielding gas supply. Process monitoring has not yet been planned. First tests are currently being carried out with the compact cutting head.

The new optical system should significantly increase the flexibility in laser cutting. The small size even enables the system to process areas difficult to access, and the low weight facilitates highly dynamic movements during 3D processing.

The development is a joint project of Fraunhofer Institutes for Applied Solid State Physics IAF (Freiburg), for Laser Technology ILT (Aachen) and for Production Technology IPT (Aachen). The optical system will also be presented at the LASER World of PHOTONICS 2017 in Munich. There, at the joint Fraunhofer stand A2.431, the experts will be available to answer all of your questions.

Fraunhofer Institute for Laser Technology ILT

Fraunhofer Institute for Laser Technology ILT