Our range of services

When laser beam sources of high power and beam quality are used in laser material processing, delivery systems are required to guide the radiation at high dynamics to the processing location and to focus it there precisely. In close cooperation with research partners, Fraunhofer ILT develops system solutions for customized manufacturing tasks that offer high processing speed, precision and efficiency.

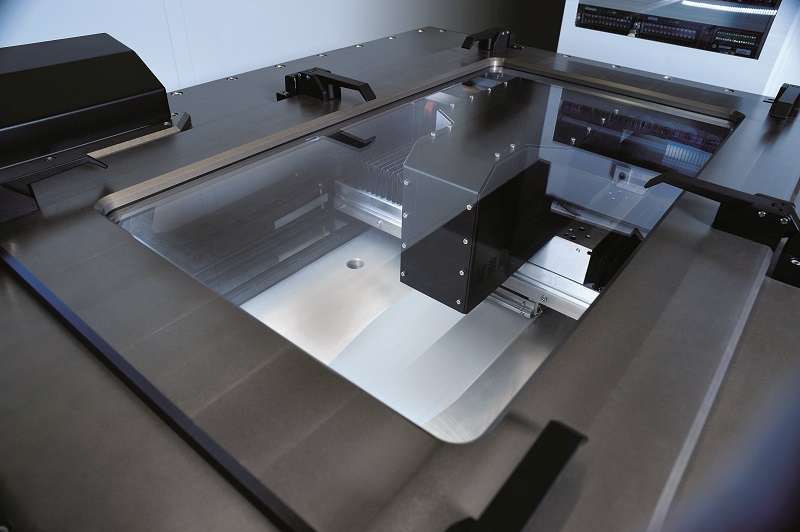

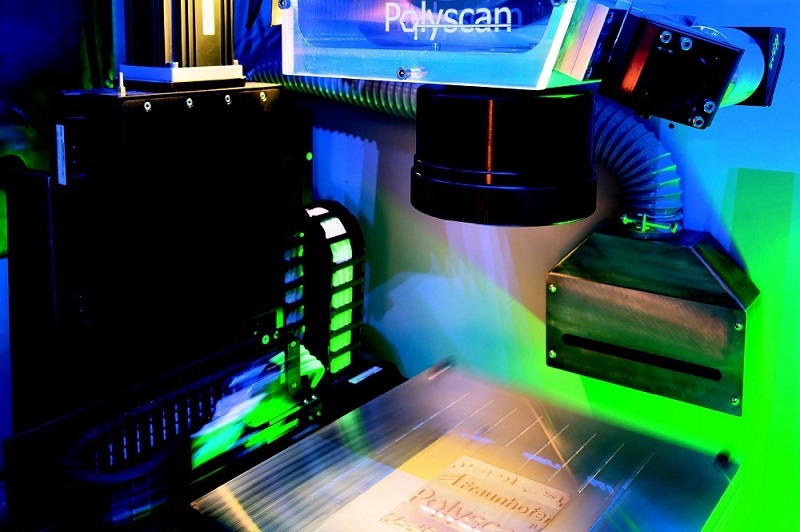

In surface processing with ultrashort pulse lasers, for example, optical systems based on polygon scanners and acousto-optical modulators (AOM) reach high processing speeds. These systems enable users to apply new machining processes and scale existing ones. In the field of high-speed machining with laser cutting, the industry uses combinations of high-precision, high-speed laser position controls and laser scanners with synchronously coupled machine-axis systems. For additive manufacturing with laser powder bed fusion, for example, multiple laser scanner systems with gantry positioning systems are combined with associated control solutions to scale processing speed and build space. For the Laser Material Deposition (LMD) process, Fraunhofer ILT is developing adaptive control concepts to capture component geometries in the machine and implement adaptive machining processes. In addition, the institute is refining system solutions that enable active path correction in the area of combined beam positioning by robots and scanners using adapted sensor technology.

The institute focuses its work in control technology on sensor integration in existing systems, real-time control of components and sensors for high-precision position detection, control and component position detection. Fraunhofer ILT develops software modules for the control and automation of processes, which are optimized in particular for laser material processing.

The range of services we offer includes conducting feasibility studies, developing tailor-made machines and control systems, integrating developed processes into existing production environments as well as conducting workshops and consulting on an individual basis.

Fraunhofer Institute for Laser Technology ILT

Fraunhofer Institute for Laser Technology ILT