Our range of services

Digitalization means alteration, change, adaptation. For technical systems new sensors or complete system solutions are required to build bridges between the real and the digital world. In automation technology, components with new interfaces have been developed that can usually be integrated into modern systems with minimal effort. Existing manufacturing systems often present a challenge, especially in the case of missing solutions for digital sensing.

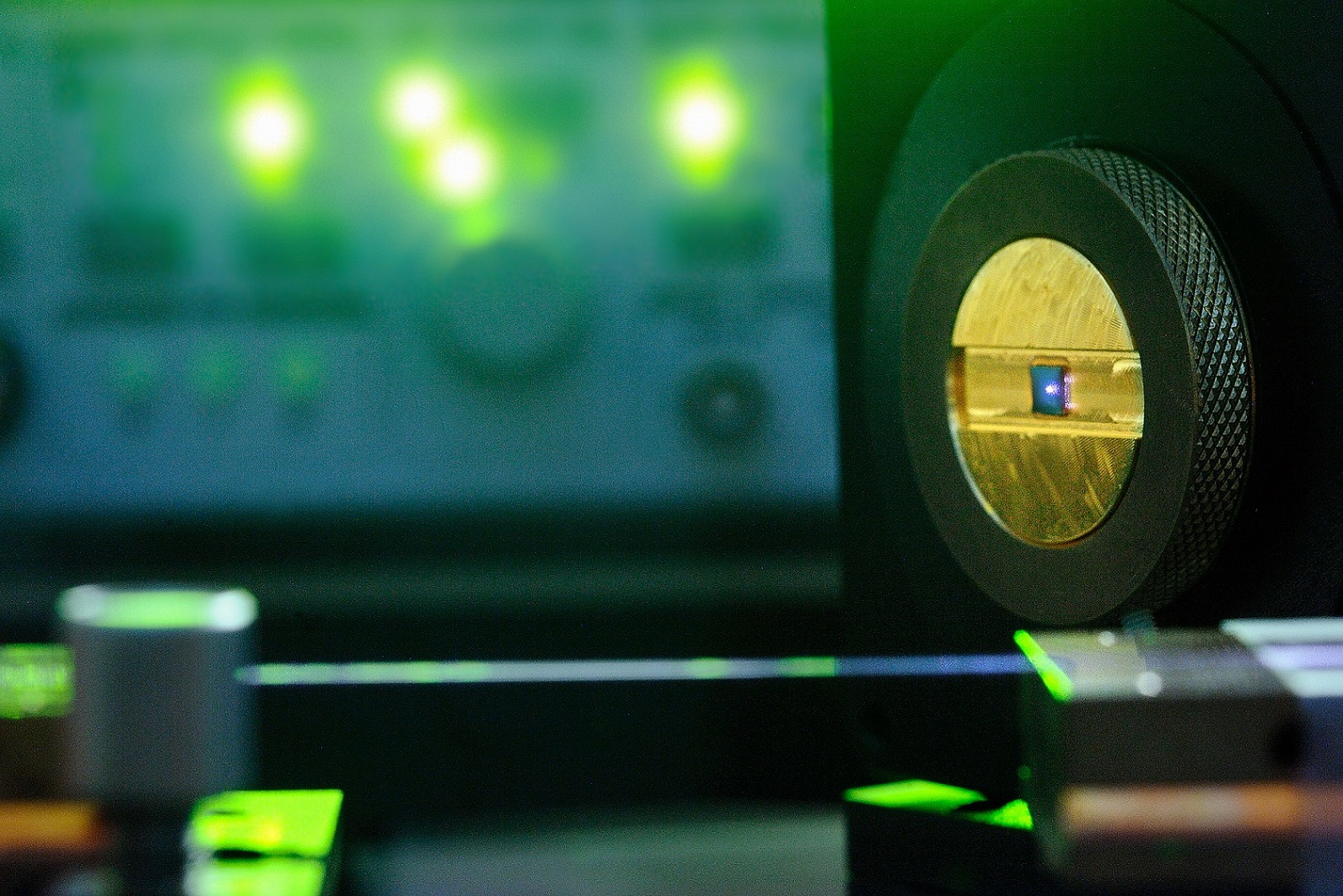

Fraunhofer Institute for Laser Technology ILT

Fraunhofer Institute for Laser Technology ILT