Linden, S., Kreinest, L., Willenborg, E.,

CAM-NC-Datenkette für die effiziente 3D-Bearbeitung.

JOT Journal für Obenflächentechnik 62, 58-61 (2022)

https://doi.org/10.1007/s35144-022-1651-x

Kumstel, J., Roosmawangca, P. R.,

Laserstrahlumschmelzen von Blechkanten.

SCHWEIßEN UND SCHNEIDEN 74, 392-395 (2022)

Nüsser, C., Willenborg, E.:

High-speed laser micro polishing of TiAl6V4.

Journal of Laser Applications 34(1), 012025- (2022)

https://doi.org/10.2351/7.0000383 (Open Access)

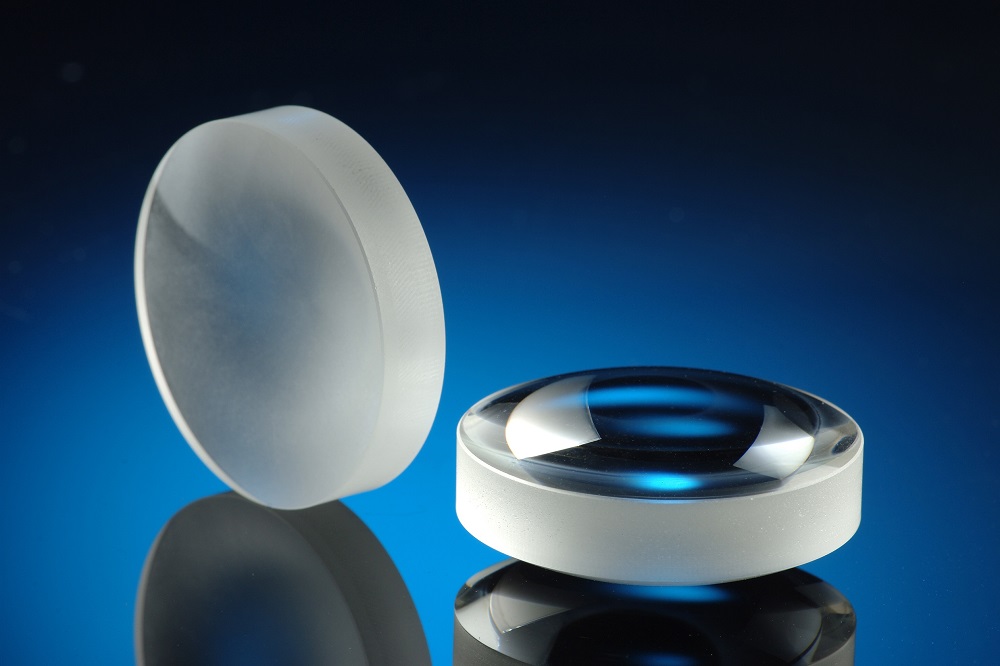

Trum, C., Jung, M., Schmidbauer, B., Sitzberger, S., Willenborg, E., Rascher, R.:

Hybrid-process-chain for polishing optical glass lenses – HyoptO.

SPIE Optical Engineering + Applications, 24 AUGUST - 4 SEPTEMBER 2020, Online Only.

Proceedings Volume 11487, Optical Manufacturing and Testing XIII, 11487, 1-10 (2020)

http://dx.doi.org/10.1117/12.2568400

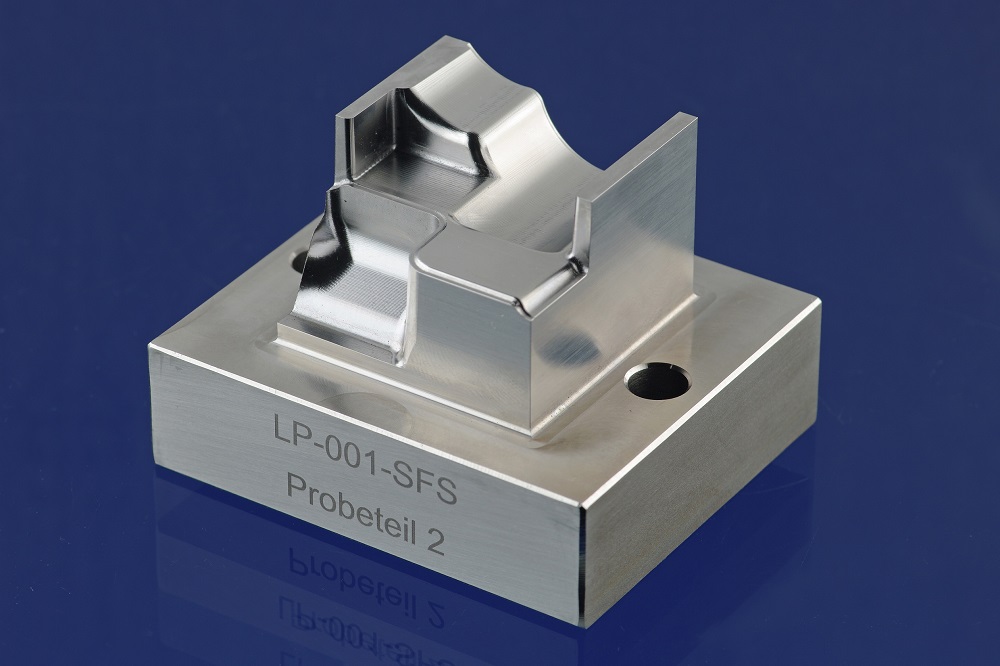

Braun, K., Willenborg, E., Schleifenbaum, J.H.:

Laser polishing as a new post process for 3D-printed polymer parts.

Procedia CIRP 94, 134-138 (2020)

https://doi.org/10.1016/j.procir.2020.09.026

Jung, M., Trum, C., Schmidbauer, B., Willenborg, E., Rascher, R.:

Non-ablative removal of sub surface damages in ground optical glass substrates by controlled melting of thin surface layers using CO2-laser radiation.

Seventh European Seminar on Precision Optics Manufacturing, 31 March - 1 April 2020, Teisnach, Germany.

Proceedings Volume 11478, Seventh European Seminar on Precision Optics Manufacturing; 1147804, (2020)

http://dx.doi.org/10.1117/12.2564801

Temmler, A., Comiotto, M., Ross, I., Kuepper, M., Liu, D.M., Poprawe, R.:

Surface structuring by laser remelting of 1.2379 (D2) for cold forging tools in automotive applications.

Journal of Laser Applications 31(2), 22017-12 (2019)

https://doi.org/10.2351/1.5070077

Kumstel, J., Lüken, S.:

Deburring and rounding of sheet metals and functionally relevant edges of parts using laser radiation.

MATEC Web of Conferences 190 - (2018)

https://doi.org/10.1051/matecconf/201819002003

Teller, M., Ross, I., Prünte, S., Temmler, A., Küpper, M., Poprawe, R., Schneider, J.M., Hirt, G.:

Probing the potential of structured and surface functionalized tools for dry cold forging of aluminium.

MATEC Web of Conferences 190 - (2018)

https://doi.org/10.1051/matecconf/201819014010

Teller, M., Ross, I., Temmler, A., Poprawe, R., Prünte, S., Schneider, J.M., Hirt, G.:

Investigation of Friction Conditions in Dry Metal Forming of Aluminum by Extended Conical Tube-Upsetting Tests.

Key Engineering Materials 767, 189-195 (2018)

https://doi.org/10.4028/www.scientific.net/KEM.767.189

Ross, I., Temmler, A., Küpper, M., Prünte, S., Teller, M., Schneider, J.M., Poprawe, R.:

Laser Polishing of Cold Work Steel AISI D2 for Dry Metal Forming Tools: Surface Homogenization, Refinement and Preparation for Self-Assembled Monolayers.

Key Engineering Materials 767, 69-76 (2018)

https://doi.org/10.4028/www.scientific.net/KEM.767.69

Teller, M., Prünte, S., Ross, I., Temmler, A., Schneider, J. M., Hirt, G.:

Tribological investigations of the applicability of surface functionalization for dry extrusion processes.

20th International ESAFORM Conference on Material Forming, 26–28 April 2017 Dublin, Ireland.

AIP Conference Proceedings 1896, 140001- (6 S.) (2017)

https://doi.org/10.1063/1.5008157

Temmler, A., Roß, I., M. Cortina, M., Poprawe, R.:

Oberflächenfunktionalisierung des Werkstoffs 1.2379+ mittels Randschichtumschmelzen mit Laserstrahlung zur Entwicklung von angepassten Oberflächentopographien für das schmiermittelfreie Kaltfließpressen von Aluminium.

Dry Metal Forming 3, 62-72 (2017)

Teller, M., Hirt, G. Roß, I., Temmler, A., Poprawe, R., Prünte, S., Schneider, J.M.:

Konzept zur Bearbeitung und tribologischen Prüfung von Fließ-pressmatrizen für das Trockenumformen von Aluminium.

Dry Metal Forming 3, 73-80 (2017)

Kumstel, J.:

Enhancement of the area rate for laser macro polishing.

WLT/LiM Lasers in Manufacturing Conference 2017. Munich, June 26-29 2017.

Proceedings of World of Photonics, (8 S.)2017

Nüsser, C., Schneider, S.:

Influence of pulse duration and scanning direction on the deformation of edges during laser micro polishing.

WLT/LiM Lasers in Manufacturing Conference 2017. Munich, June 26-29 2017.

Proceedings of World of Photonics, (11 S.) (2017)

Anemone, G., Weingarten, C., Al Taleb, A., Prieto, C., Farías, D.:

Ultrasmooth metal thin films on curved fused silica by laser polishing.

APPLIED PHYSICS LETTERS 111, 1-4 (2017)

https://doi.org/10.1063/1.4999917

Weingarten, C., Steenhusen, S., Hermans, M., Willenborg, E., Schleifenbaum, J.H.:

Laser polishing and 2PP structuring of inside microfluidic channels in fused silica.

Microfluid Nanofluid 21, 1-9 (2017)

https://doi.org/10.1007/s10404-017-2000-x

Weingarten, C., Braun, K., Willenborg, E.:

Combination of Laser-based Process Steps for Optics Manufacturing.

Optical Design and Fabrication 2017 (Freeform, IODC, OFT): [Proceedings] - OSA Washington, D.C., 2017. Paper OTu3B.6, 1-3 (2017).

https://doi.org/10.1364/OFT.2017.OTu3B.6

Weingarten, C., Uluz, E., Schmickler, A., Braun, K., Willenborg, E., Temmler, A., Heidrich, S. :

Glass processing with pulsed CO2 laser radiation.

APPLIED OPTICS 56(4), 777-783 (2017)

https://doi.org/10.1364/AO.56.000777

Weingarten, C., Schmickler, A., Willenborg, E., Wissenbach, K., Poprawe, R.:

Laser polishing and laser shape correction of optical glass.

Journal of Laser Applications 29(1), 11702- (2017)

http://dx.doi.org/10.2351/1.4974905

Teller, M., Hirt, G., Roß,I., Temmler, A.,Poprawe, R., Prünte, S.:

Abschätzung der umformtechnischen Grenzen des schmierstofffreien Kaltfließpressens von Aluminium anhand von Tribometerversuchen.

Dry Metal Forming 2, 56-61 (2016)

Teller, M., Bambach, M., Hirt, G., Roß, I., Temmler, A., Poprawe,R., Bolvardi, H.,Prünte,S., Schneider, J.M.:

Methodik zur Entwicklung von interaktionsminimierten Oberflächen-schichten für das schmiermittelfreie Kaltfließpressen von Aluminium.

Dry Metal Forming 1, 34-41 (2015)

Teller, M., Bambach, M., Hirt, G., Ross, I., Temmler, A., Poprawe, R., Bolvardi, H., Prünte, S., Schneider, J.M.:

Investigation of the suitability of surface treatments for dry cold extrusion by process-oriented tribological testing.

International Conference on Material Forming, 18, 2015, Graz. ESAFORM 2015. Vol.1 : Selected, peer reviewed papers from the 18th International ESAFORM Conference on Material Forming, (Key engineering materials 651-653), 473-479 (2015)

https://doi.org/10.4028/www.scientific.net/KEM.651-653.473

Nüsser, C., Kumstel, J., Kierowski, T., Diatlov, A., Willenborg, E.:

Process- and Material-Induced Surface Structures During Laser Polishing

Advanced Engineering Materials 17, 268-277 (2015)

https://doi.org/10.1002/adem.201400426

Oreshkin, O., Küpper, M., Temmler, A., Willenborg, E.:

Active reduction of waviness through processing with modulated laser power

Journal of Laser Applications 27 (2), 22004 (7 S.) (2015)

https://doi.org/10.2351/1.4906622

Weingarten, C., Heidrich, S., Wu, Y., Willenborg, E.:

Laser polishing of glass

Optifab 2015. Ed. by J. L. Bentley, S. Stoebenau. Rochester, N.Y., October 12-15, 2015, Proc. SPIE 9633. 963303 (10 S.) (2015)

https://doi.org/10.1117/12.2200972

Heidrich, S., Weingarten, C., Willenborg, E., Poprawe, R.:

Polishing and form correction with laser radiation

Optical Fabrication and Testing, Kohala Coast, Hawaii, United States, June 22-26, 2014. Fabrication Process Technology I (OTu1B.4) (3 S.) (2014).

https://doi.org/10.1364/OFT.2014.OTu1B.4

Preussner, J., Oeser, S., Pfeiffer, W., Temmler, A., Willenborg, E.:

Microstructure and residual stresses of laser remelted surfaces of a hot work tool steel

International Journal of Materials Research 105 (4), 328-336 (2014)

https://doi.org/10.3139/146.111027

Temmler, A., Walochnik, M. A., Willenborg, E., Wissenbach, K.:

Surface structuring by remelting of titanium alloy TI6AL4V

In: Proceedings 33rd ICALEO International Congress on Applications of Lasers & Electro–Optics, October 19-23, 2014, San Diego, CA, USA

Paper ID 1401, (10 S.) (2014)

https://doi.org/10.2351/1.4906387

Willenborg, E., Heidrich, S.: Temmler, A.:

Highlights of the 1st Conference on Laser Polishing LaP 2014, Aachen, Germany

Optical Fabrication and Testing, Kohala Coast, Hawaii, United States, June 22-26, 2014. Fabrication Process Technology I (OTu1B.1) (3 S.) (2014)

https://doi.org/10.1364/OFT.2014.OTu1B.1

Temmler, A., Pütsch, O., Stollenwerk, J., Willenborg, E., Loosen, P.:

Optical set-up for dynamic superposition of three laser beams for structuring and polishing applications

Optics Express, S.1387-1393, (2014)

https://doi.org/10.1364/oe.22.001387

Heidrich, S., Richmann, A., Schmitz, P., Willenborg, E., Wissenbach, K., Loosen, P., Poprawe, R.:

Optics manufacturing by laser radiation

Optics and Lasers in Engineering, S. 34-40 (2014)

https://doi.org/10.1016/j.optlaseng.2014.03.001

Hauschild, D., Kumstel, J., Willenborg, E.:

Produktivität bei der Laserpolitur deutlich steigern

WT-Online 103 (11/12), 1-5 (2013)

Heidrich, S.:

Fast freeform processing

Mikroniek 53, (3), 48-50 (2013)

Heidrich, S., Richmann, A., Willenborg, E.:

Laser-based optics manufacturing

3rd EOS Conference on Manufacturing of Optical Components (EOSMOC 2013). International Congress Centre Munich (ICM), Germany (2 S.) (2013)

Kumstel, J., Kirsch, B.:

Polishing titanium- and nickel-based alloys using cw-laser radiation

Physics Procedia 41, 362-371 (2013)

https://doi.org/10.1016/j.phpro.2013.03.089

Nüsser, C., Sändker, H., Willenborg, E.:

Pulsed laser micro polishing of metals using dual-beam technology

Phys. Procedia 41, 346-355 (2013)

https://doi.org/10.1016/j.phpro.2013.03.087

Pütsch, O., Temmler, A., Stollenwerk, J., Willenborg, E., Loosen, P.:

Active optical system for laser structuring of 3D surfaces remelting

Laser Beam Shaping XIV. Ed.: Andrew Forbes, Todd E. Lizotte. Proc. SPIE 8843, 88430D (8 S.) (2013)

https://doi.org/10.1117/12.2023306

Willenborg, E., Ross, I., Kumstel, J., Flemmer, J.:

Werkzeugmaschine für das Laserpolieren

wt Werkstattstechnik online 103, (6), 465-469 (2013)

Heidrich, S., Richmann, A., Willenborg, E.:

Development of a laser based process chain for manufacturing free form optics

Proc. SPIE 8433, 14 S., (2012)

https://doi.org/10.1117/12.922407

Heidrich, S., Richmann, A., Willenborg, E.:

Development of manufacturing freeform glass optics with laser radiation

Optical Fabrication and Testing (OFT) Monterey, Ca., June 25, 2012

3 S., (2012)

Heidrich, S., Richmann, A., Willenborg, E.:

Optics fabrication with a laser based process chain

8th International Conference on Optics-Photonics Design and Fabrication, “ODF’12”, Saint Petersburg, July, 2-5, 2012, 3 S., (2012)

https://doi.org/10.1364/OFT.2012.OW1D.2

Teki, R., Kadaksham, A. J., House, M. [et. al.]:

Alternative smoothing techniques to mitigate EUV substrate defectivity

SPIE Advanced Lithography, 12-16 February 2012, San Jose, California, United States.

Proceedings Volume 8322, Extreme Ultraviolet (EUV) Lithography III; 83220B (2012)

https://doi.org/10.1117/12.916497

Temmler, A., Willenborg, E., Wissenbach, K.:

Designing surfaces by laser remelting

Proc. of 7th International Conference on MicroManufacturing, Evanston, (8 S.) (2012)

Temmler, A., Willenborg, E., Wissenbach, K.:

Laser polishing

SPIE Photonics West – LASE, 21-26 January 2012, Moscone Center, San Francisco, California, USA, Proc. SPIE 8243, (13 S.) (2012)

https://doi.org/10.1117/12.906001

Flemmer, J.:

3D-Geometrien laserpolieren

Maschine + Werkzeug 9, 1-2, (2011)

Heidrich, S., Willenborg, E., Richmann, A.:

Development of a laser based process chain for manufacturing freeform optics

Phys. Proced. 12, 519-528, (2011)

https://doi.org/10.1016/j.phpro.2011.03.064

Nüsser, C., Wehrmann, I., Willenborg, E.:

Influence of intensity distribution and pulse duration on laser micro polishing

Phys. Proced. 12, 462-471, (2011)

https://doi.org/10.1016/j.phpro.2011.03.057

Richmann, A., Willenborg, E., Wissenbach, K.:

Laser polishing of spherical quartz lenses

2nd EOS Conference on Manufacturing of Optical Components (EOSMOC), Munich, Germany: 23 May - 25 May 2011, (2 S) (2011)

Richmann, A., Heidrich, S.:

Polieren und Abtragen von Quarzglas mit CO2-Laserstrahlung

2. Workshop Glasbearbeitung mit Laserstrahlung, 12. April 2011, Erlangen, (21 S.) (2011)

Temmler, A., Willenborg, E., Wissenbach, K.:

Design surfaces by laser remelting

Phys. Proced. 12, 419-430, (2011)

https://doi.org/10.1016/j.phpro.2011.03.053

Nüsser, C.

Gepulster Laserstrahl poliert Implantatoberflächen

MM Maschinenmarkt 44, 28-30, (2010)

Ostholt, R., Willenborg, E., Wissenbach, K.

Laser polishing of metallic freeform surfaces

ICALEO 2010. 29th International Congress on Applications of Lasers & Electro Optics, Anaheim/Ca., September 26-30, 2010. Paper 1705, (7 S.) (2010)

Richmann, A., Willenborg, E., Wissenbach, K.:

Laser polishing of fused silica

Optical Fabrication and Testing (OFT), Jackson Hole, WY, June 14-17, 2010: Laser Writing in Materials (OTuC), (3. S.) (2010)

https://doi.org/10.1364/OFT.2010.OTuC2

Richmann, A., Willenborg, E., Wissenbach, K.:

Polieren optischer Präzisionsoberflächen mit Laserstrahlung

DGaO Deutsche Gesellschaft für Angewandte Optik, 111. Jahrestagung vom 25.-29.5.2010 in Wetzlar, (2 S.) (2010)

Temmler, A., Graichen, K., Donath, J.:

Laser polishing in medical engineering

Laser Technik 7 (2), 53-57, (2010)

http://dx.doi.org/10.1002/latj.201090028

Richmann, A., Willenborg, E., Wissenbach, K.:

Laser polishing of fused silica

Proc. of the 5th Int. WLT Conf. on Lasers in Manufacturing 2009, Munich, June 15th-18 th, 2009. Ed. by A. Ostendorf [u.a.] Stuttgart: AT-Fachverlag, pp. 691-702, (2009)

Ostholt, R., Willenborg, E., Wissenbach, K.:

Laser polishing of metallic freeform surfaces

Proc. of the 5th Int. WLT Conf. on Lasers in Manufacturing 2009, Munich, June 15th-18th, 2009.

Ed. by A. Ostendorf [u.a.]

Stuttgart: AT-Fachverlag, pp. 397-401, (2009)

Willenborg, E.

Polieren mit Laserstrahlung

Kunststoffe 97, 63-66, (2007)

Fraunhofer Institute for Laser Technology ILT

Fraunhofer Institute for Laser Technology ILT