Our range of services

Many modern applications in industry or in the laboratory require uninterrupted data processing in real time and high computing power on demand. To meet such demands, Fraunhofer ILT develops solutions specific to an application for devices in manufacturing and laboratory measurement technology.

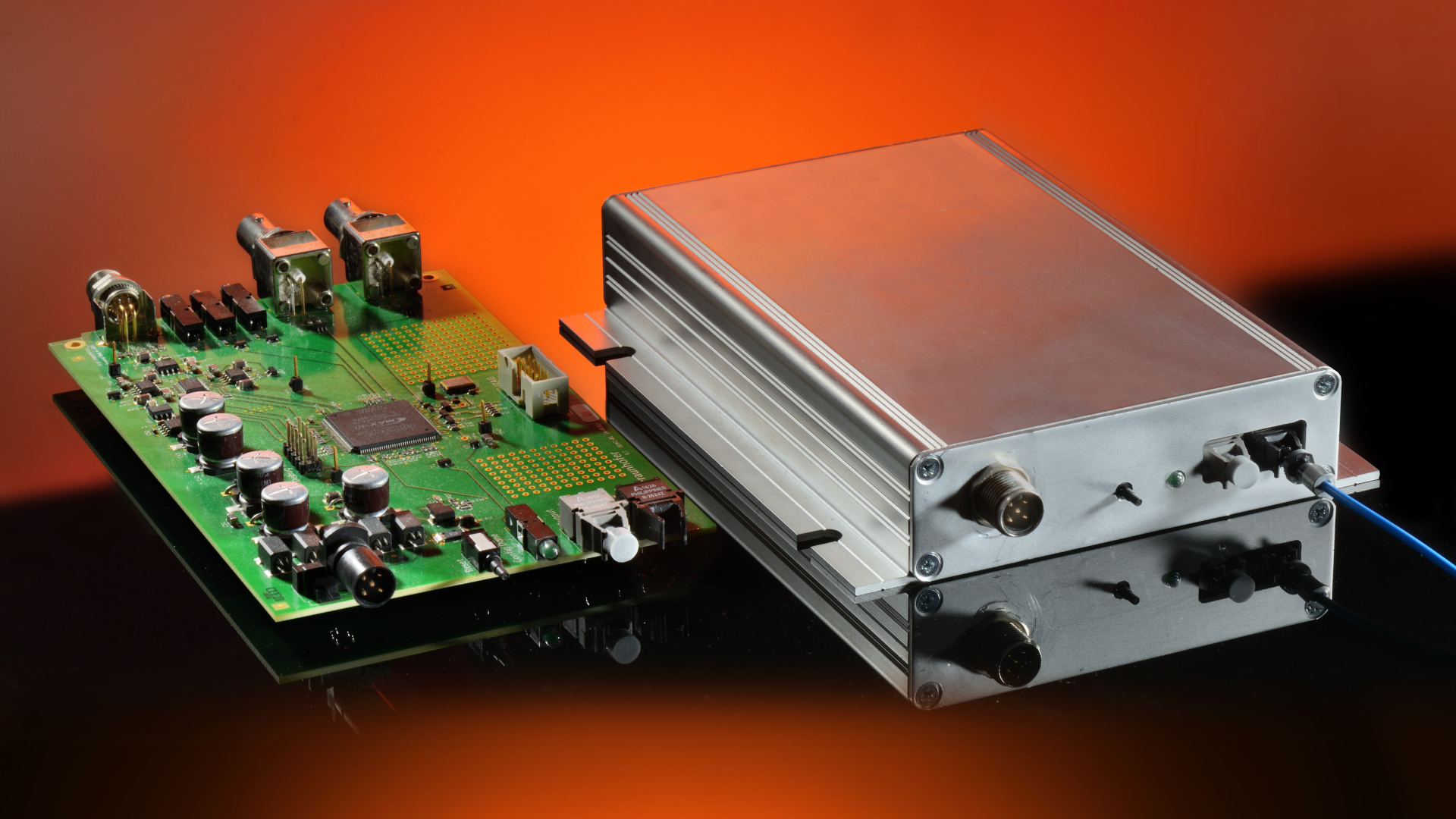

Powerful electronic units are central elements for the connection to sensors and actuators specific to a device. They can be designed as open platforms that allow specific functions to be implemented flexibly and cost-effectively. In addition, communication interfaces can be implemented into systems that are important for laser technology applications, such as for the connection of scanner systems and sensors.

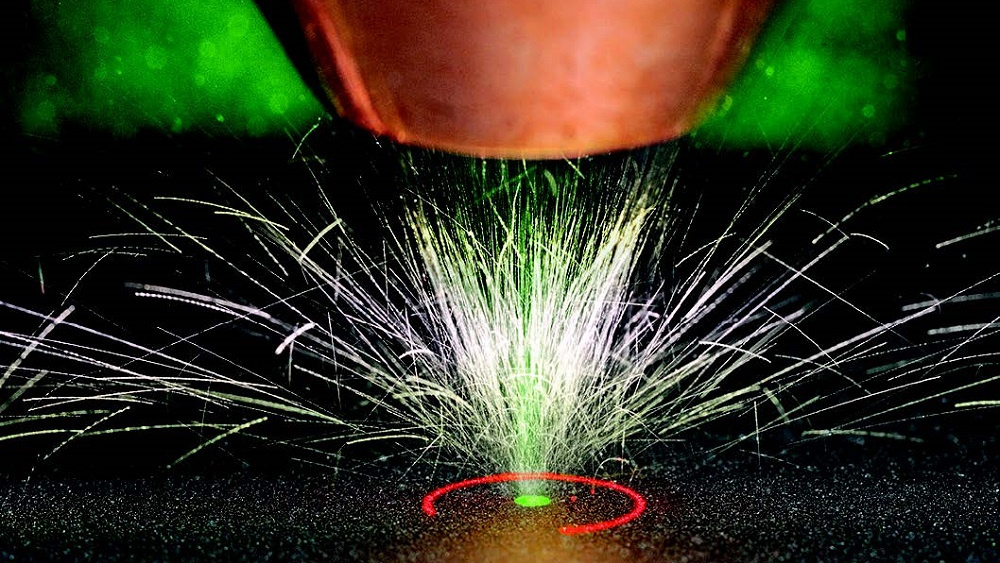

Modular concepts consisting of central base boards with versatile interfaces and a matching portfolio of peripheral boards make it possible to assemble electronic units specific to an application for new devices. This way, data can be processed in real time. Hardware interfaces also allow the connection of laser beam sources, scanners, A/D and D/A converters, encoders, photomultipliers, photodiodes, PLCs, precision scales and other modules. Applications include devices in laser measurement and laser medical technology, such as distance sensors, microsorter and laboratory devices based on fluorescence measurement technology.

The range of service we offer includes feasibility studies for customer-specific tasks, the development of new processes, components and equipment, and individual consulting.

Fraunhofer Institute for Laser Technology ILT

Fraunhofer Institute for Laser Technology ILT