Our range of services

With scanner systems adapted to an application, laser radiation can be deflected not only very quickly and precisely, but also focused on the workpiece in a targeted manner. Fraunhofer ILT develops scanners for a wide range of applications in the field of laser material processing, including processes such as drilling, ablation, cutting and welding. In additive manufacturing or for metrological tasks, the institute either adapts commercially available scanners for specific applications or develops completely new systems if scanners with the required properties are not available on the market.

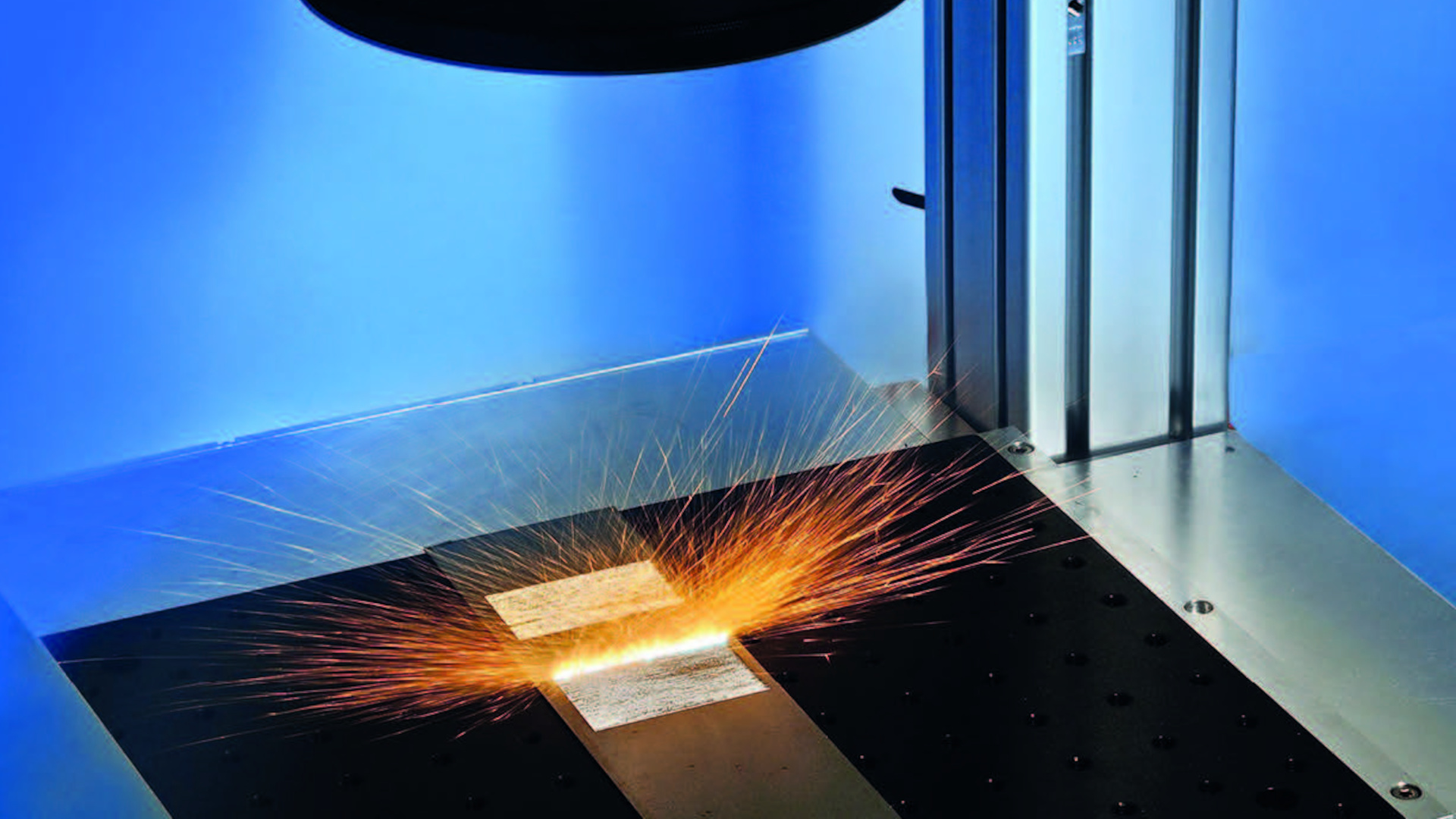

For efficient laser ablation in surface processing, for example, high average powers and high pulse repetition rates are required. With polygon scanners and acousto-optic modulators, the available power of suitable ultrafast lasers can be fully utilized, and the processed material does not overheat. As available laser power increases, these scanners also make it possible to increase productivity through high area and volume ablation rates. Applications include the cleaning and microstructuring of complex 3D surfaces or the quasi-simultaneous soldering of solar cells.

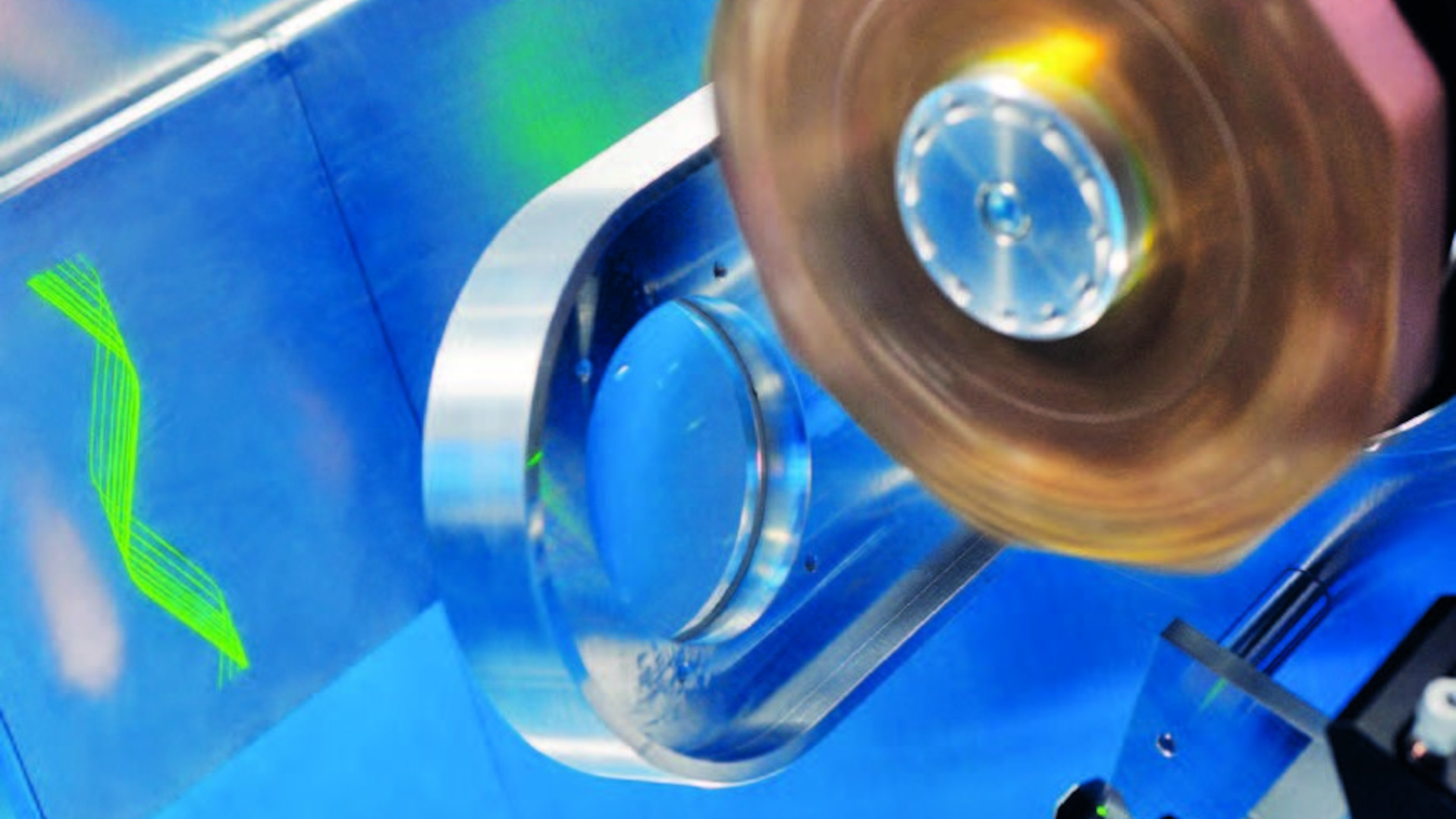

For many processes, it is advantageous to use a galvanometric laser scanner to guide the beam focus along the component surface dynamically and close to its contour. Special components and controls have been developed for these systems with short cycle times. In the field of high-speed machining, combinations of fast position controls and laser scanners with multi-axis systems are used. This way, complex structures can be joined as the robot arm guides the scanner continuously, quickly deflecting the laser beam.

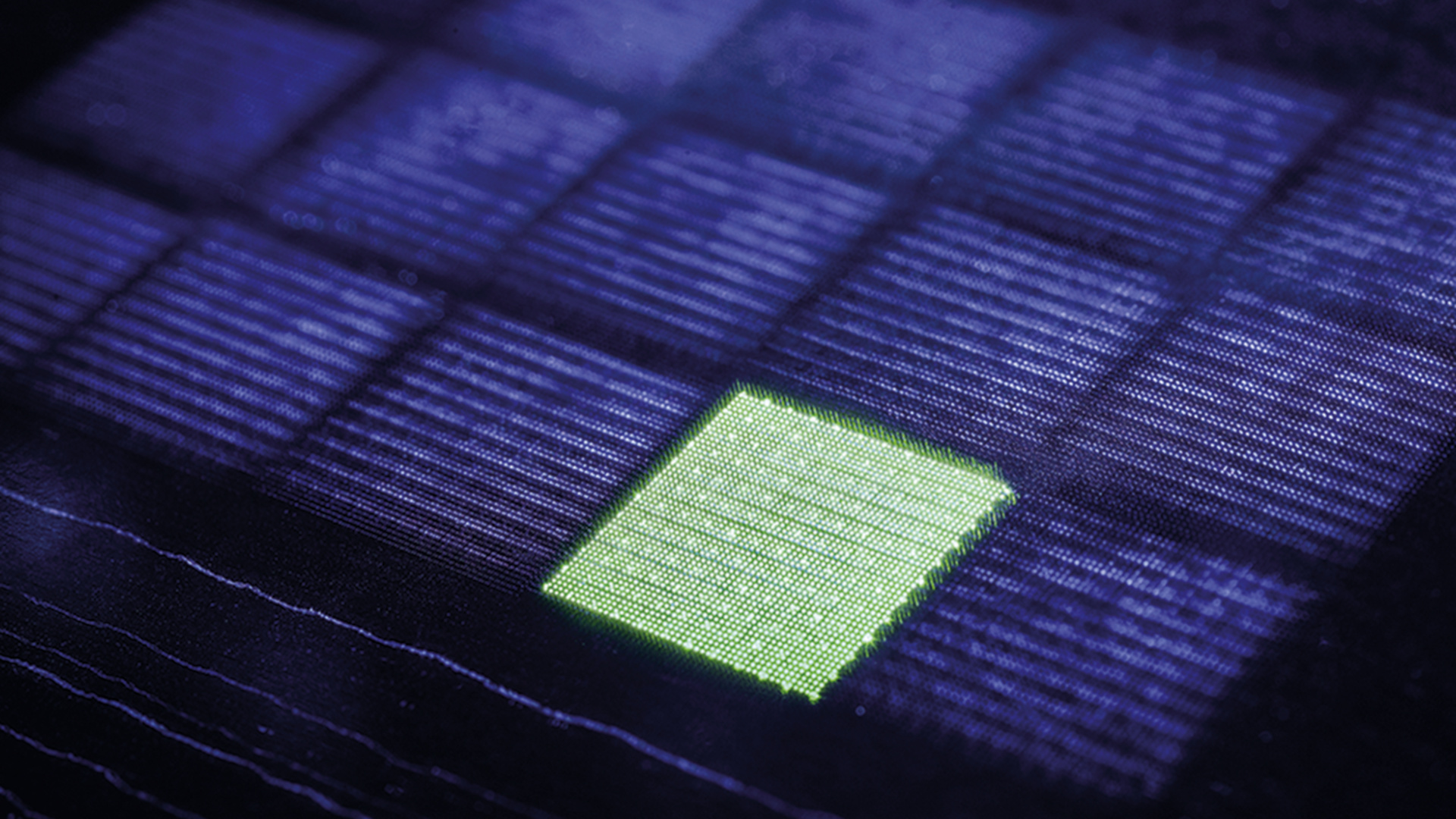

In addition, the laser beam can be split into several partial beams whose spacing can be easily adjusted. Drilling processes with drilling rates of up to 12,000 holes/s with sub-µm precision have already been implemented with this multi-beam processing for applications in filter and screen technology or for coating masks.

The range of services we offer includes feasibility studies, the development of components and processes, validation and integration, simulations and comprehensive consulting.

Fraunhofer Institute for Laser Technology ILT

Fraunhofer Institute for Laser Technology ILT