Process and System Technology for Hybrid Production of Large Components with Laser Material Deposition (LMD)

In nearly every field of manufacturing, components and the resulting products are becoming increasingly complex and more individual. At the same time, companies need to shorten the time between developing an idea for a new product and launching it on the market in order to safeguard the future of their business. Established manufacturing processes offer little or no scope for improvement in this respect. Additive manufacturing holds out the promise of considerable time savings and process innovations that would create value in manufacturing companies as well as the ability to realize entirely new product features. Achieving these goals requires some key ingredients to be made available at an early stage of the product development process, including product, process and material data for additive manufacturing processes, innovative materials, and new kinds of production equipment. The results of the ProLMD development project will play a key role in strengthening Germany’s international competitiveness over the long term in line with the German Federal Government’s High-Tech Strategy.

Hybrid manufacturing of large, high-performance components

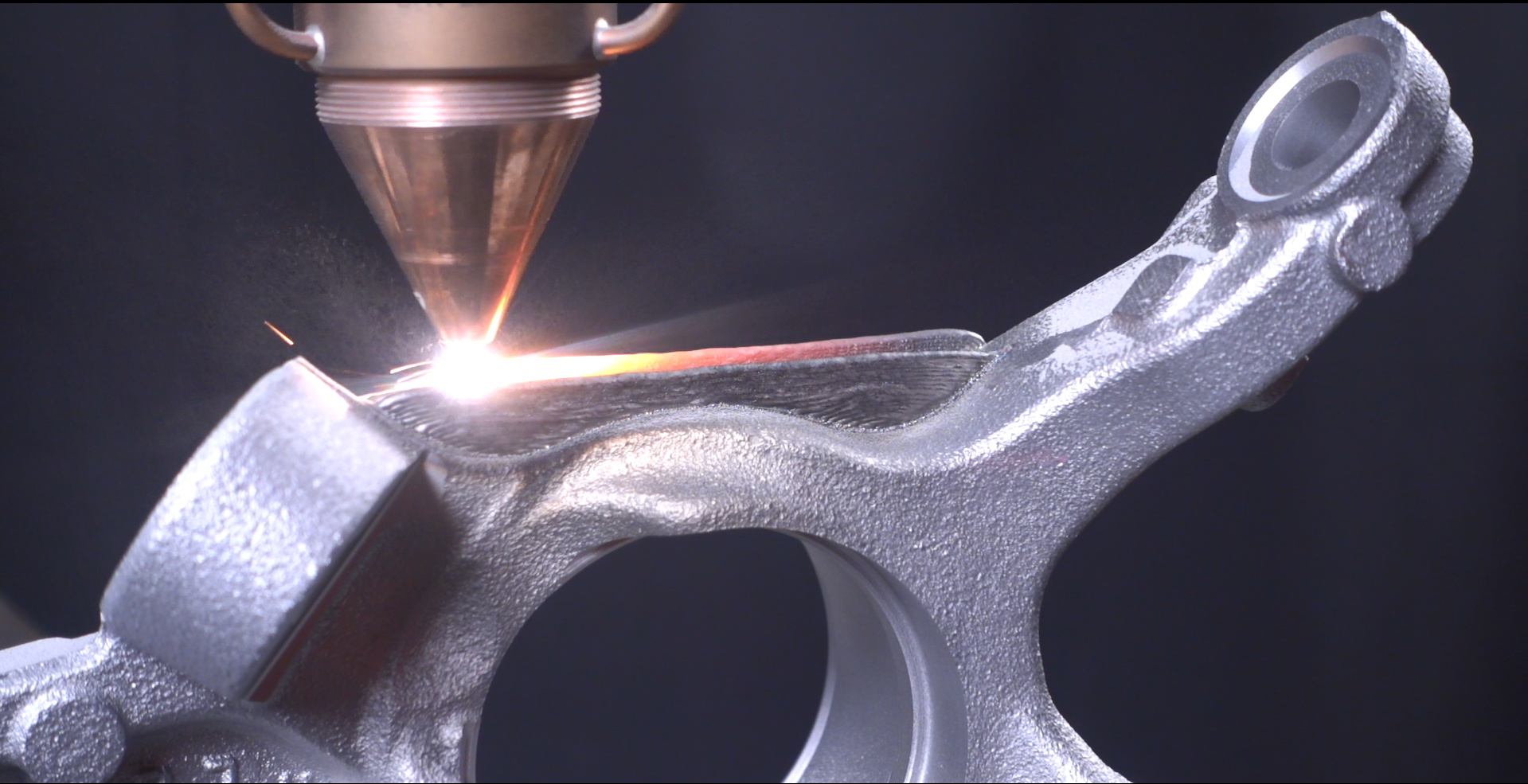

Today’s methods of producing high-performance and lightweight components (e.g. for aircraft) typically involve ablating up to 90 percent of the raw material, which must then be recycled. Hybrid manufacturing offers an alternative to these standard methods. Starting with conventionally produced blanks, it makes use of additive manufacturing processes to add additional geometric elements. Laser cladding, also known as laser metal deposition (LMD), is a particularly suitable additive process in this context. Its advantages include the ability to add geometric elements to three-dimensional parts of virtually unlimited size using an automated process. Compared to other additive processes, LMD also offers relatively high build rates.

This technology opens up a wealth of opportunities to manufacture innovative products at a reasonable cost – for example locally reinforced structural components for aircraft. Commercially available LMD machines are expensive and can only handle parts up to a certain size, however. This is because laser metal deposition requires the use of a shielding gas to protect sensitive materials against oxidation. The current approach of placing the entire chamber in an inert gas atmosphere incurs significant costs while limiting the size of the components that can be machined.

The aim of the ProLMD project is to develop an economical process chain including the systems technology and LMD processes. The results of the project will be demonstrated on demonstrator components provided by the industry partners involved in the project. The ProLMD systems technology is based on industrial robots, an approach that reduces costs and boosts flexibility in terms of component geometry and size. Further benefits will arise from the development of a flexible shielding gas system which will only deploy shielding gas where it is actually required. The system will be rounded off with a new laser machining head that can work with both wire and powder as the filler material, plus a suitable CAM system for hybrid manufacturing. In parallel, research into LMD processes is being conducted for a range of materials in both wire and powder form. Experts will be performing detailed material analyses as a basis for applying the technique to highly loaded components and implementing geometric inspections of the built-up components.

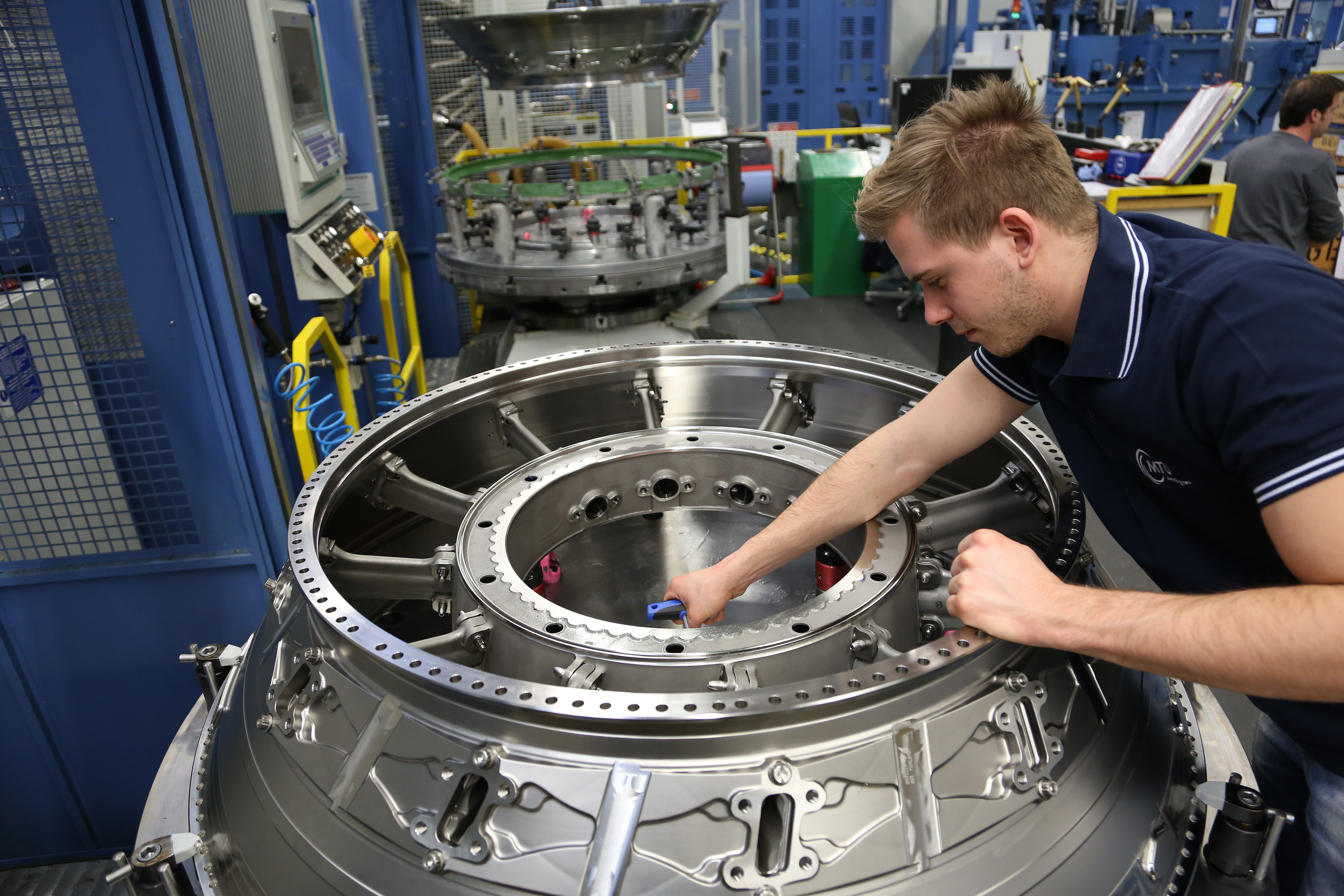

The process chain will be demonstrated with applications from the project partners MTU Aero Engines (adding functional elements to an engine casing), Airbus (reinforcing components using 3D ribbing) and Daimler (adapting a press tool in car body manufacturing).

Offering cost reductions of over 10 percent for the entire process chain, a more economical use of resources, and increased flexibility at the product development stage, the results of this project could also provide technological and cost benefits to other industries such as aerospace and energy generation as well as the tool making sector with its high proportion of SMEs.

Fraunhofer Institute for Laser Technology ILT

Fraunhofer Institute for Laser Technology ILT