Laser Measurement Technology

Lasers are ideally suited for the precise measurement of physical, chemical or biological quantities in various fields of application. Fraunhofer ILT develops laser measurement processes, e. g., for tasks in manufacturing and inline-capable process control, and implements them in prototypes and small series together with customers and partners. In this field, the institute is also focusing on material and bioanalytics, identification and analysis technology in the field of recycling, and raw materials as well as measurement and testing technology.

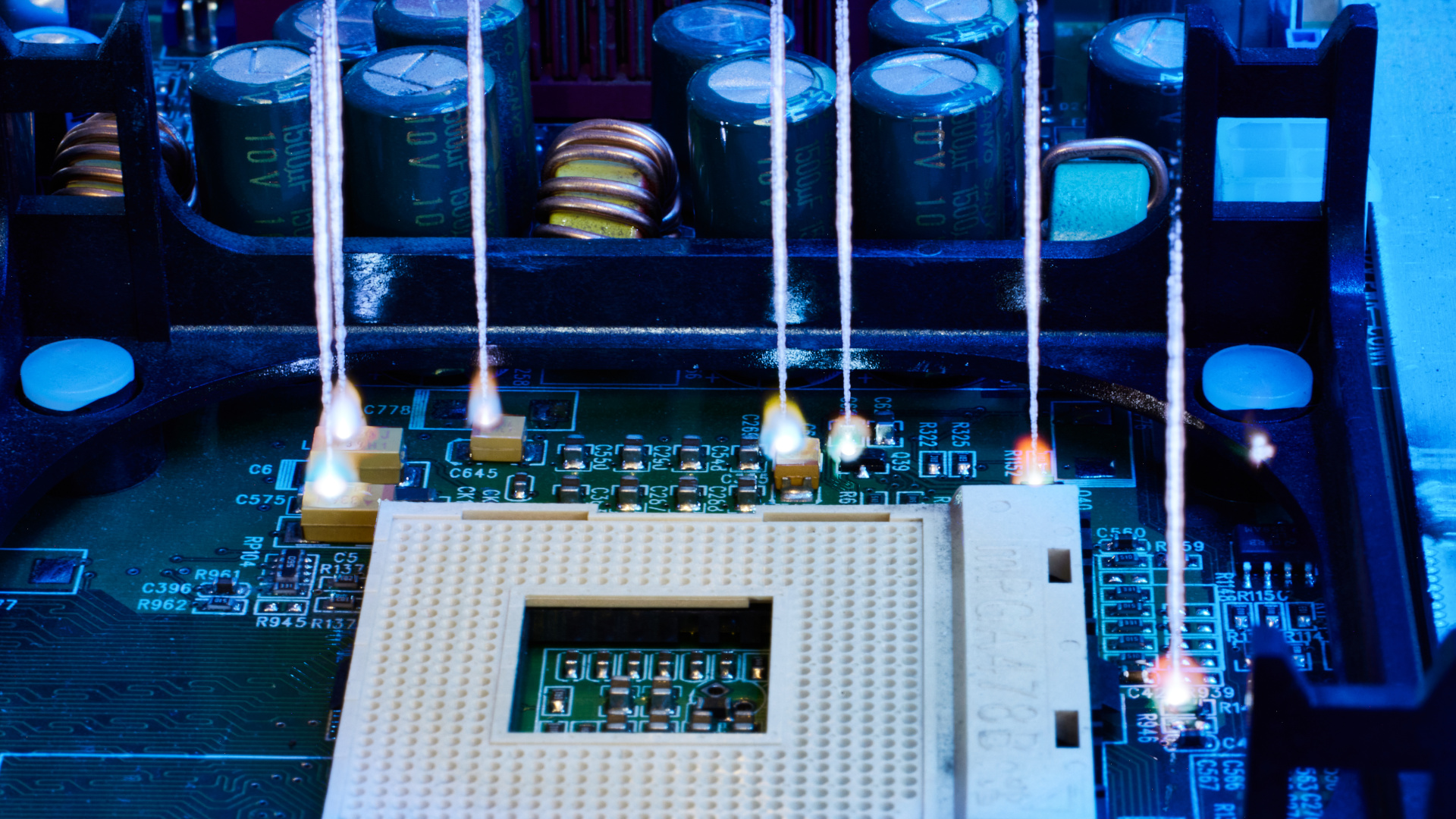

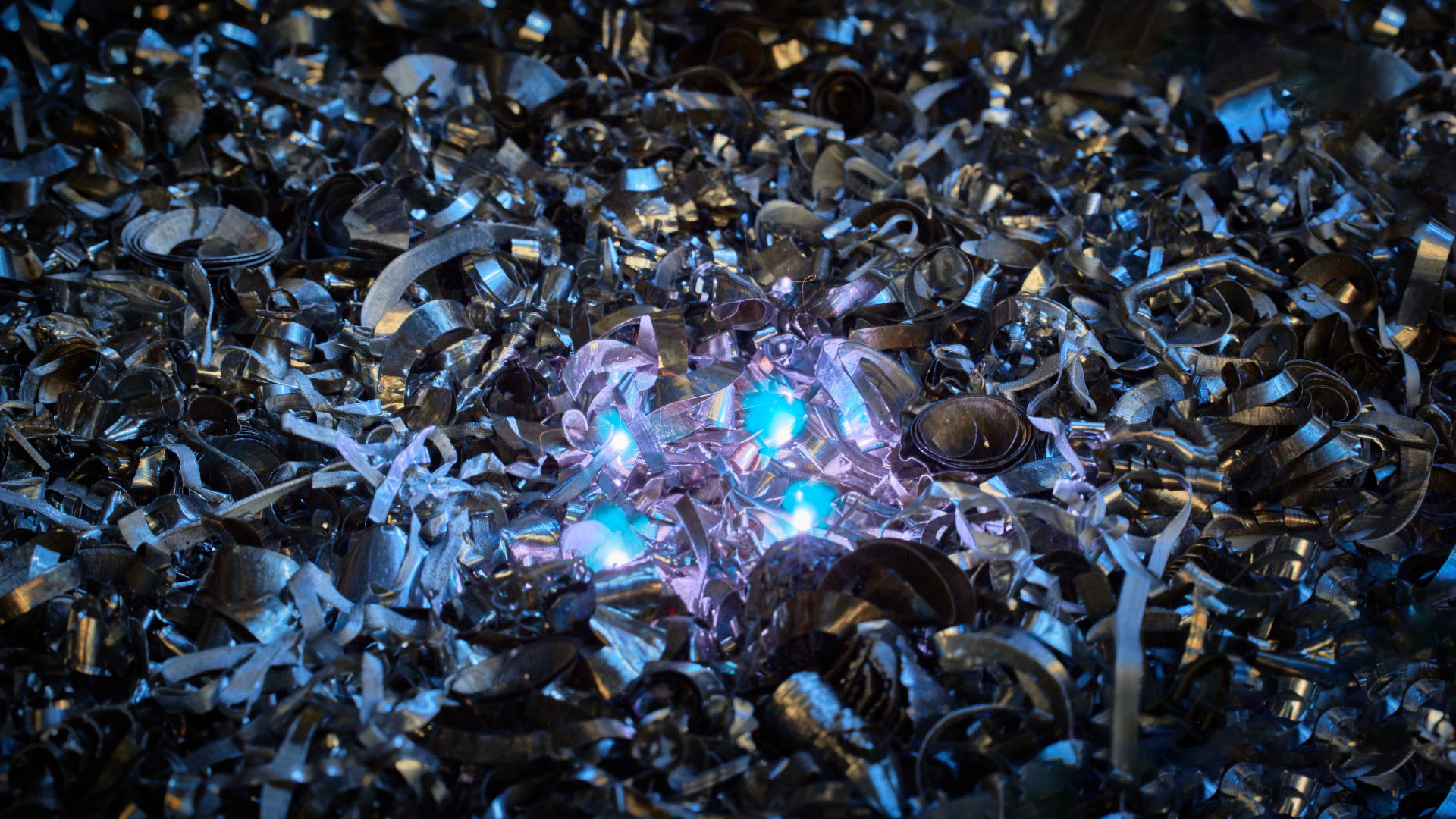

In materials analysis, Fraunhofer ILT has profound know-how in spectroscopic measurement processes at its disposal. Applications in this field include automatic quality assurance, the monitoring of process parameters and the online analysis of, for example, old electronic components, metal scrap or exhaust gases, dust and wastewater. Among other processes, laser emission spectroscopy (laser-induced breakdown spectroscopy LIBS) is used, allowing particularly fast and accurate material identification. In addition to process development, the institute manufactures prototype systems and mobile systems for industrial use.

Together with international partners, Fraunhofer ILT is also breaking new ground in researching modern recycling processes. Solutions are being developed jointly – with laser technology – to make processes more effective and efficient.

Fraunhofer Institute for Laser Technology ILT

Fraunhofer Institute for Laser Technology ILT