Our range of services

The measurement of physical, chemical or biological parameters is critical in many manufacturing tasks. Fraunhofer ILT develops various laser measurement processes for tasks in production and for in-line process control; together with customers and partners, it implements these processes in prototypes and small series.

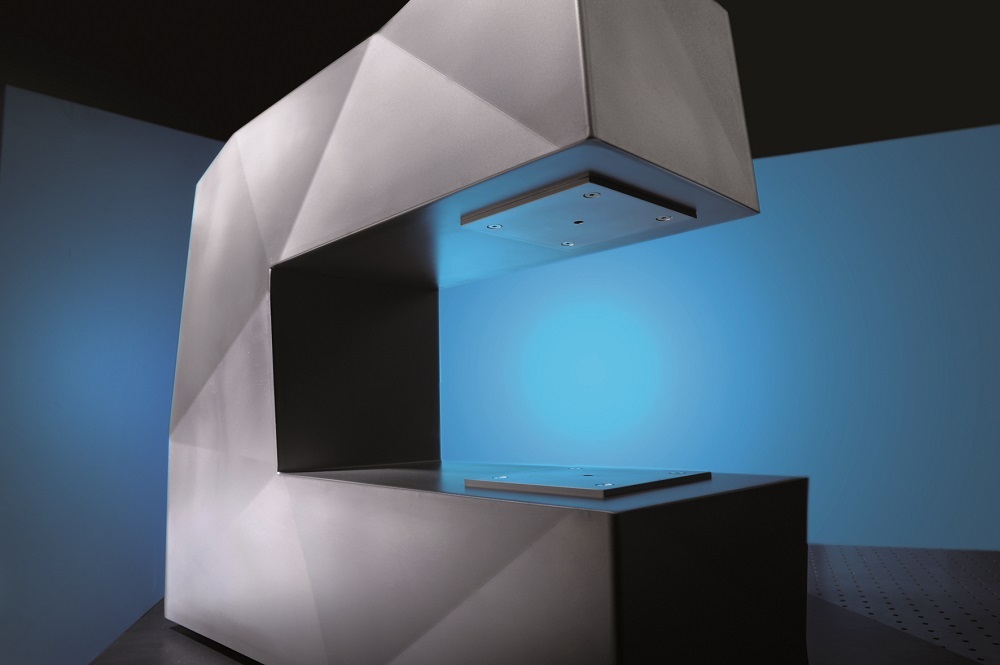

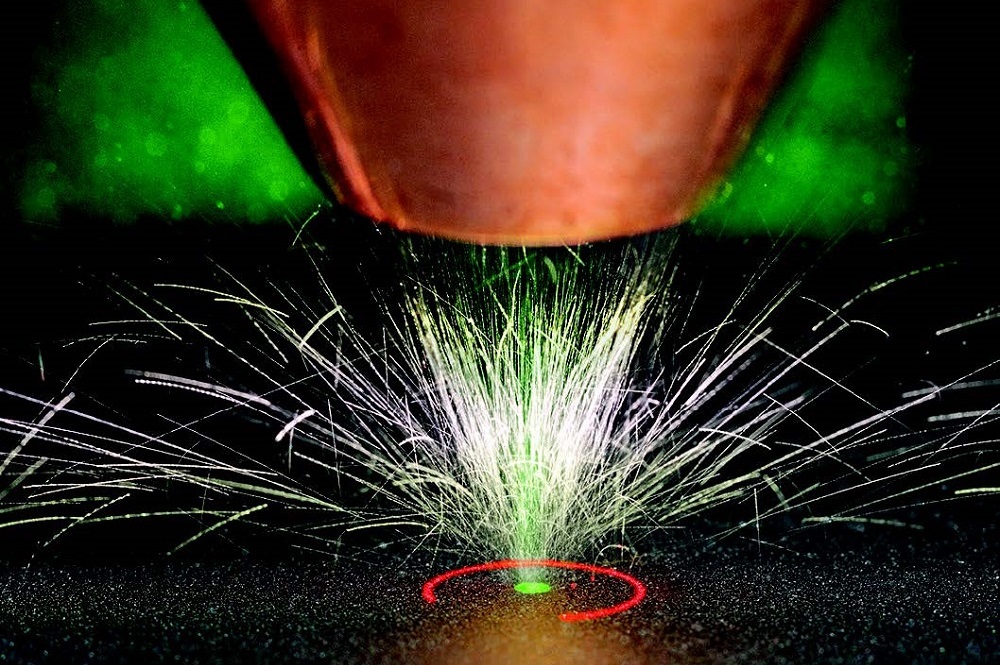

For example, thanks to an absolute measuring interferometric sensor technology developed at Fraunhofer ILT, geometrical properties of components can be measured with very high accuracy and high throughput. During Laser Material Deposition, this sensor can detect geometrical characteristics, such as the applied layer thickness. In real-time, therefore, it is possible to react to deviations from the target geometry so that process deviations can be detected and compensated for early on. Further fields of application for interferometric sensors are inline monitoring and control during laser beam melting, laser drilling and laser microstructuring.

In the field of recycling, for example, laser spectroscopic measuring methods are ideal for automated sorting processes. Metals, ceramics, glasses, slag, or raw materials can be identified and sorted very quickly. Rare valuable materials, such as technology metals in components on electronic circuit boards, can also be identified and specifically reclaimed.

The range of services offered include feasibility studies, the development of components and procedures for production metrology, support for the integration of new technologies in industrial manufacturing processes and the start of continuous operation in production, as well as individual consultation on customerized laser measurement systems.

Fraunhofer Institute for Laser Technology ILT

Fraunhofer Institute for Laser Technology ILT