The LPBF process

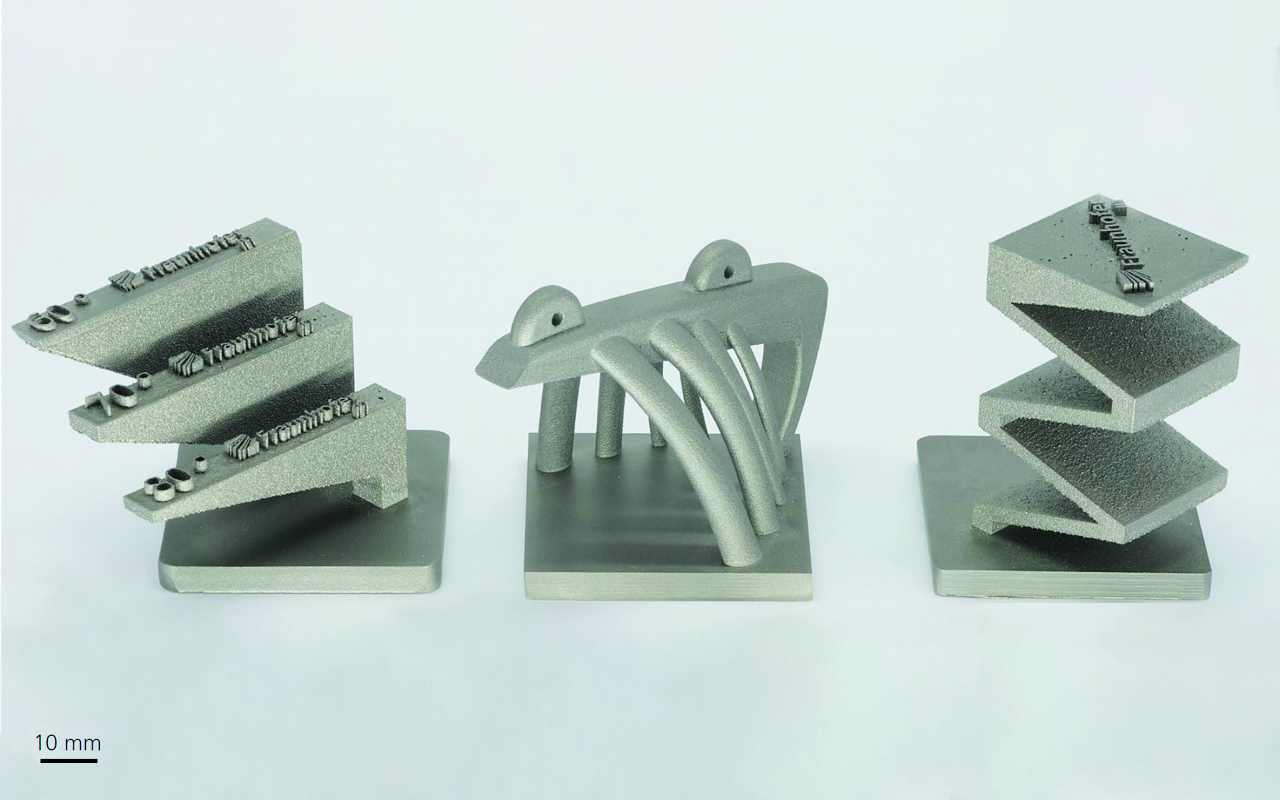

Since it applies layer upon layer using CAD data, LPBF can produce highly complex components from metallic materials without the need for forming tools, components that cannot be manufactured using conventional production processes such as casting or machining. The LPBF process is often described in simplified terms as "metallic 3D printing," but in reality it is influenced by numerous process parameters and disturbance variables, which make it far more complex. Only by selectively adjusting these process parameters while simultaneously controlling the disturbance variables can the user ensure that the manufactured component fulfills the desired requirements.

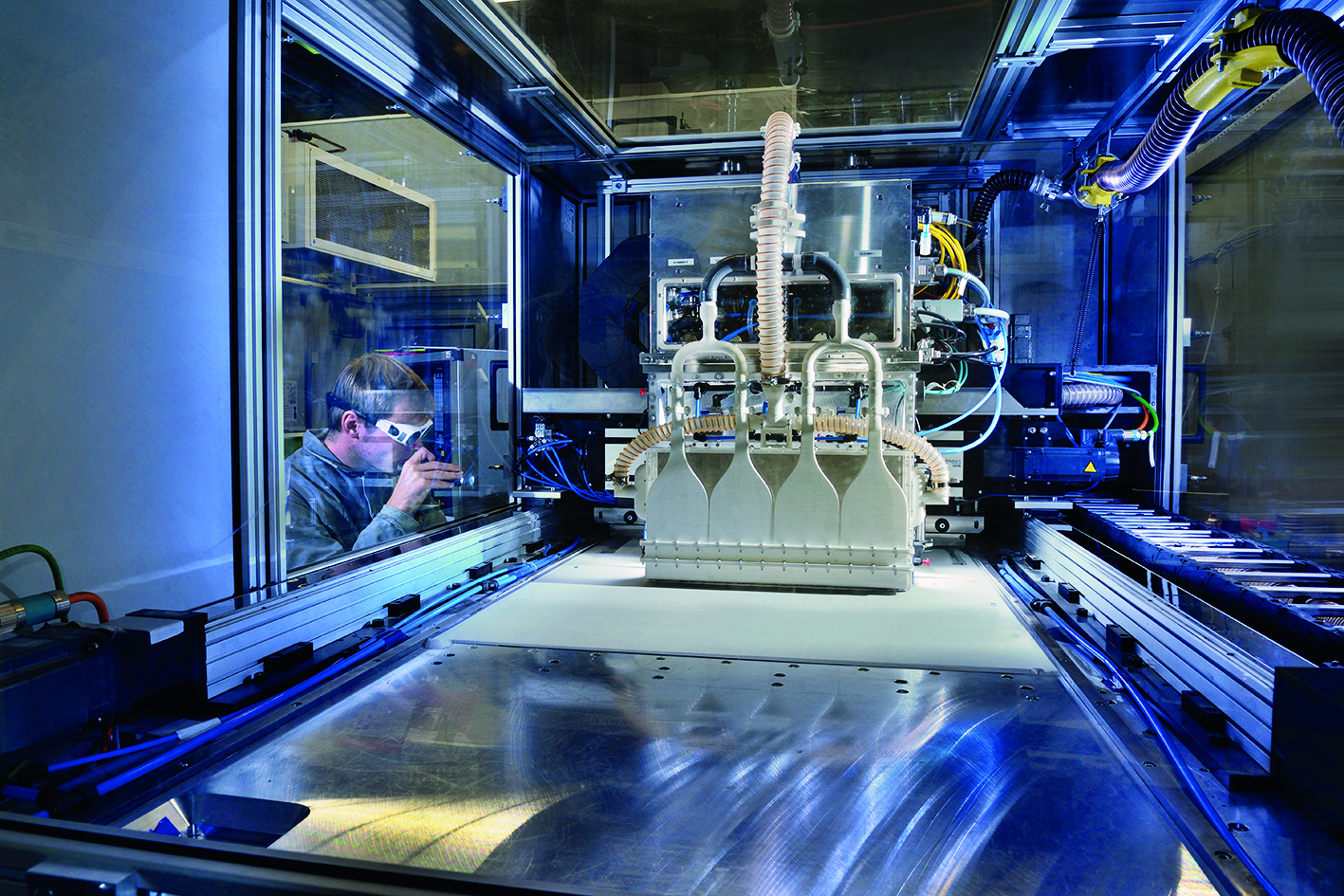

LPBF machines have a movable build platform onto which a powder layer is applied with an application unit. The laser radiation required for the LPBF process is deflected by a galvanometer scanner and focused by F-Theta or Vario optical systems. Metallic materials are processed in an inert gas atmosphere, with the gas circuit taking over the task of removing process by-products. The machine components used influence various properties of the overall system, such as process speed and component quality. Thus, to use laser powder bed fusion economically, a company has to appropriately select and combine individual components for the corresponding application. The experts at Fraunhofer ILT can help you optimize the LPBF process and the associated system technology individually for your application and, if necessary, develop new strategies for solving your tasks.

Fraunhofer Institute for Laser Technology ILT

Fraunhofer Institute for Laser Technology ILT