Kratz, M., Rückle, L., Kalupka, C., Reininghaus, M., Häfner, C.,

Dynamic correction of optical aberrations for height-independent selective laser induced etching processing strategies.

OPTICS EXPRESS 31, 26104-26119 (2023)

https://doi.org/10.1364/OE.493088 (Open Access)

Danylyuk, S., Osbild, M., Korr, L., Fischer, M., Delmdahl, R., Reininghaus, M.,

Sub-micrometer structuring of surfaces with deep UV lasers.

SPIE LASE, 2023, 28 Jan - 3 Feb 2023, San Francisco, California, United States.

Proceedings Volume 12409, Laser-based Micro- and Nanoprocessing XVII (Proc. of SPIE), 1240911 (2023)

http://dx.doi.org/10.1117/12.2647865

Köller, J., Sassmannshausen, A., Kratz, M., Voß, J.,

Particle Re-Deposition During Ultrashort Pulse Laser Ablation of ITO Thin Films Using Single- and Multi-Beam Processing.

Journal of Laser Micro/Nanoengineering 17, (2022)

https://doi.org/10.2961/jlmn.2022.03.2007 (Open Access)

Grubert, N., Hofmann, O., Hesker, M., Stollenwerk, J., Holly, C.,

Beam shaping for large-area laser structuring in a roll-to-roll process.

SPIE Optical Engineering + Applications 21-26 August 2022, San Diego, California, United States.

Proceedings Volume 12216, Novel Optical Systems, Methods, and Applications XXV; 1221604 (2022)

https://doi.org/10.1117/12.2632926

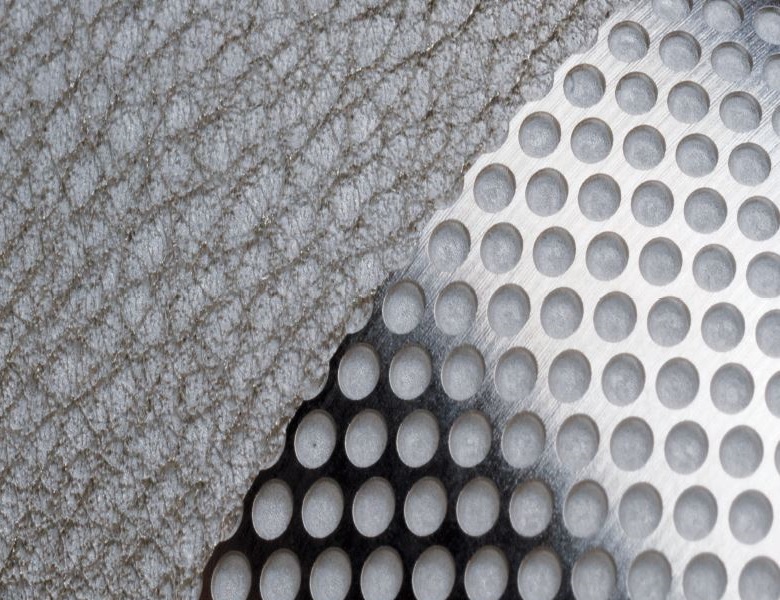

Lanfermann, A., Barthels, T., Nießen, M., Abels, P., Klass, G., Riester, C., Pham, T.Q., Steffens, O.,

INNOVATIVE FILTER MODULE TO SEPARATE MICROPLASTICS FROM WASTEWATER – SIMCONDRILL.

FILTECH 2022, 8-10. March 8-10, 2022, Cologne, Germany. FILTECH : March 8-10, 2022, Cologne, Germany:the filtration event, 10 S., (2022)

Lanfermann, A., Barthels,T., Nießen, M., Abels, P., Klass, G., Riester, C., Pham, T.Q., Steffens, O.,

Innovative Filtermodule für die Abscheidung von Mikroplastik aus Abwasser.

GWF: Wasser, Abwasser 163, 51-54 (2022)

Lanfermann, A., Barthels, T., Nießen, M., Abels, P., Klass, G. , Riester, C., Pham, T.Q. Steffens, O.,

Innovative Filtermodule für die Abscheidung von Mikroplastik aus Abwasser.

F&S Filtrieren & Seprarieren F&S 01 | 2022, 28-30 (2022)

Pongratz L., Vannahme, K.,

Beam Shaping the Direct Laser Interference Patterning Spot.

Journal of Laser Micro/Nanoengineering 17, 42-49 (2022)

https://doi.org/10.2961/jlmn.2022.01.2007

Pongratz, L., Lantzsch, T., Schwedt, A.:

Impact on surface topography of interference patterned steel and brass using an ultrashort pulsed laser source.

Journal of Laser Applications 34, 31201- (2022)

https://doi.org/10.2351/7.0000555

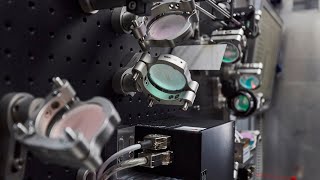

Lüttgenau, B., Brose, S., Danylyuk, S., Stollenwerk, J., Loosen, P., Holly, C.:

Design and realization of an in-lab EUV dual beamline for industrial and scientific applications.

SPIE PHOTOMASK TECHNOLOGY + EUV LITHOGRAPHY | 27 SEPTEMBER - 8 OCTOBER 2021.

Proceedings Vol.11854, International Conference on Extreme Ultraviolet Lithography 2021; 1185419 (2021)

https://doi.org/10.1117/12.2600935

Pongratz, L., Vannahme, K.

Automated spatial period variation for Direct Laser Interference Patterning DLIP.

SPIE LASE, 2021, Online Only., Laser-based Micro- and Nanoprocessing XV; (Proc. of SPIE 11674),116740P-, (2021) 11674

https://doi.org/10.1117/12.2579507

Pongratz, L., Vannahme, K.:

Beam shaping the Direct Laser Interference Patterning spot.

The 22nd International Symposium on Laser Precision Microfabrication, June 8-11, 2021 (Web Conference).

Proceedings of LPM2021, #21-021- (7 S.), (2021)

He, C., Vannahme, K., Gillner, A.:

High-Efficiency Sub-Micrometer Multi-Beam Interference Structuring for Large-Scale Surface Using Ultrashort Laser Pulses.

JOURNAL OF LASER MICRO/NANOENGINEERING 14, 95-99 (2019)

https://doi.org/10.2961/jlmn.2019.01.0016

He, C., Vannahme, K., Gillner, A.:

High-efficiency sub-micrometer multi-beam interference structuring for large-scale surface using ultrashort laser pulses.

The 19th International Symposium on Laser Precision Microfabrication Edinburgh Conference Centre, Heriot-Watt University, Edinburgh, UK, 25-28 June, 2018.

Proceedings of LPM2018, #18-042, (X S.), (2018)

Kalupka C., Schmalstieg, M., Reininghaus, M.:

Ultrashort Pulse Processing of Transparent Ceramics: The Role of Electronic and Thermal Damage Mechanisms.

J LASER MICRO NANOEN 13 (2), 126-130 (2018)

https://doi.org/10.2961/jlmn.2018.02.0012

Gretzki, P., Gillner, A.:

Programmable diffractive optic for multi-beam processing: applications and limitations.

SPIE Nanoscience + Engineering, Aug. 25 2017, San Diego, California.

Proc. of SPIE 10347, Optical Trapping and Optical Micromanipulation XIV, 103470V (13 S.) (2017)

https://doi.org/10.1117/12.2274448

Großmann, D., Reininghaus, M., Kalupka, C., Jenne, M., Kumkar, M.:

In-situ microscopy of front and rear side ablation processes in alkali aluminosilicate glass using ultra short pulsed laser radiation.

OPTICS EXPRESS 25 (23), 28478- (11 S.) (2017)

https://doi.org/10.1364/OE.25.028478

Temmler, A., Küpper, M., Walochnik, M.A., Lanfermann, A., Schmickler, T., Bach, A., Greifenberg, T., Oreshkin, O., Willenborg, E., Wissenbach, K., Poprawe, R.:

Surface structuring by laser remelting of metals.

JLA 29, 012015 (12 S.) (2017)‘

https://doi.org/10.2351/1.4972414

Boehr, S., Nolis, P., Brenner, A., Reininghaus, M., Lamß, M., Müller, B.:

Laserbasierte Fertigungstechniken und additive Fertigung.

Galvanotechnik 108, 1672-1677 (6 S.) (2017)

Knapp, W., Gillet, V., Courant, B., Aubignat, E., Costil, S., Langlade, C.:

Enhancement of low pressure cold sprayed copper coating adhesion by laser texturing on aluminium substrates

SPIE LASE, 2017, San Francisco, California, United States. Proceedings Volume 10097, High-Power Laser Materials Processing: Applications, Diagnostics, and Systems VI, 100970P (2017).

https://doi.org/10.1117/12.2250870

Kalupka, C., Großmann, D., Reininghaus, M.:

Evolution of energy deposition during glass cutting with pulsed femtosecond laser radiation

Appl. Phys. A 123(5), 376 (7 S.) (2017)

https://doi.org/10.1007/s00339-017-1000-8

Carstens, H., Högner, M., Saule, T., Holzberger, S., Lilienfein, N., Guggenmos, A, Jocher, C., Eidam, T., Esser, D., Tosa, V. , Pervak, V., Limpert, J., Tünnermann, A., Kleineberg, U., Krausz, F., Pupeza, I.:

High-harmonic generation at 250 MHz with photon energies exceeding 100 eV.

Optica 3 (4), 366-369 (2016)

https://doi.org/10.1364/OPTICA.3.000366

Blattmann, V., Trusheim, D.:

Hybrid laser-etching-process for wafer texturing

Energy Procedia 77, 766-773 (2015)

https://doi.org/10.1016/j.egypro.2015.07.108

Finger, J., Kalupka C., Reininghaus, M.:

High power ultra-short pulse laser ablation of IN718 using high repetition rates

J. Materials Processing Technol. 226 (Dec.), 221-227 (2015)

https://doi.org/10.1016/j.jmatprotec.2015.07.014

Fornaroli, C., Holtkamp, J., Gillner, A.:

Dicing of thin silicon wafers with ultra-short pulsed lasers in the range from 200 fs up to 10 ps

J. Laser Micro/Nanoeng. 10 (2), 229-233 (2015)

http://dx.doi.org/10.2961/jlmn.2015.02.0022

Oreshkin, O., Küpper, M., Temmler, A., Willenborg, E.:

Active reduction of waviness through processing with modulated laser power

Journal of Laser Applications 27 (2), 22004 (7 S.) (2015)

https://doi.org/10.2351/1.4906622

Reininghaus, M., Ivanov, D., Maß, T.W.W., Eckert, S., Juschkin, L., Garcia, M. E., Taubner, T., Poprawe, R.,

Nanophotonic applications of fs-laser radiation induced nanostructures and their theoretical description

Optically Induced Nanostructures. Hrsg. v. König, Karsten / Ostendorf, Andreas. Berlin: De Gruyter, 25-46 (2015)

https://www.ncbi.nlm.nih.gov/books/NBK321724/

Mincuzzi, G., Vesce, L., Schulz-Ruhtenberg, M., Gehlen, E., Reale, A., Di Carlo, A., Brown, T. M.:

Taking temperature processing out of dye-sensitized solar cell fabrication: Fully laser-manufactured devices

Adv. Energy Mat. 4, 1400421 (8 S.) (2014)

https://doi.org/10.1002/aenm.201400421

Temmler, A., Walochnik, M. A., Willenborg, E., Wissenbach, K.:

Surface structuring by remelting of titanium alloy TI6AL4V

In: Proceedings 33rd ICALEO International Congress on Applications of Lasers & Electro–Optics, October 19-23, 2014, San Diego, CA, USA

Paper ID 1401, ISBN 9781940168029 (10 S.) (2014)

https://doi.org/10.2351/1.4906387

Zibner, F., Ryll, J., Holtkamp, J., Gillner, A.:

High precision 2.5D laser cutting of thin nitinol and polyurethane for medical applications

ICALEO, 32th International Congress on Applications of Lasers& Electro-Optics : October 6-10, 2013, Miama/Fl., USA., M4154 (6 S.) (2013)

https://doi.org/10.2351/1.5062977

Eppelt, Urs:

Elektronenschauer im Glas

Laser Community, 2/2012, pp. 24-25 (2012)

Eppelt, U., Russ, S., Hartmann, C., Sun, M., Siebert, C., Schulz, W.:

Diagnostic and Simulation of PS-Laser Cutting

Proc. of the 31st Int. Congress on Applications of Lasers & Electro-Optics, ICALEO September 23-27, 2012, Anaheim, CA, USA, Paper M504, (10 S.) (2012)

http://dx.doi.org/10.2351/1.5062548

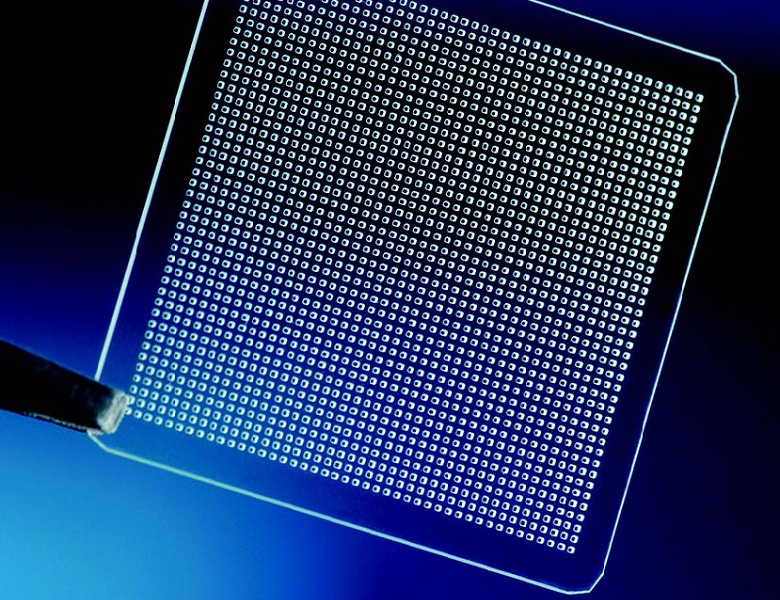

Hambach, N., Hartmann, C., Holtkamp, J., Gillner, A.:

Stability limits of laser drilled hole arrays on large areas

J. Laser Appl. 24 (3), (5 S.) (2012)

https://doi.org/10.2351/1.3702944

Michaeli, W., Eilbracht, S., Scharf, M., Hartmann, C., Bobzin, K., Bagcivan, N., Theiß, S.:

Application of variothermal heating concepts for the production of microstructured films using the extrusion embossing process

J. Polymer Eng. 32, 95-101 (2012)

https://doi.org/10.1515/polyeng-2012-0502

Mincuzzi, G., Schulz-Ruhtenberg, M., Vesce, L., Reale, A., Di Carlo, A., Gillner, A., Brown, T.:

Laser processing of TiO2 films for dye solar cells: a thermal, sintering, throughput and embodied energy investigation

Progress in Photovoltaics: Research and Applications

Wiley Online Library (2012)

https://doi.org/10.1002/pip.2261

Mincuzzi, G., Zardetto, V., Vesce, L., Schulz-Ruhtenberg, M., Gillner, A., Reale, A., di Carlo, A., Brown, T.:

Raster scanning laser and UV processing of nanocrystalline TiO2 films for sintering in dye solar cells: Device performance, throughput and embodied energy

MRS Online Proceedings Library 1447, (6 S.) (2012)

https://doi.org/10.1557/opl.2012.1092

Schaefer, M., Schulz-Ruhtenberg, M., Holtkamp, J., Gillner, A,:

Comparison of laser ablation of transparent conductive materials on flexible and rigid substrates

Proc. LOPE-C, Munich, 39-43 (2012)

Sun, M., Eppelt, U., Russe, S., Hartmann, C., Siebert, C., Zhua, J., Schulz:

Laser ablation mechanism of transparent dielectrics with picosecond laser pulses

Proc. SPIE 8530, (9 S.) (2012)

https://doi.org/10.1117/12.976062

Wu, S., Huang, J., Beckemper, S., Gillner, A., Wang, K., Bubeck, C.:

Block polymer supramolecular assemblies hierarchically structured by three-beam interference laser ablation

J. Mat. Chem. 22 (11), 4989-4995 (2012)

https://doi.org/10.1039/C2JM16442F

Beckemper, S., Huang, J., Gillner, A., Wang, K.:

Generation of periodic micro- and nano-structures by parameter-controlled three-beam laser interference technique

J. Laser Micro/Nanoeng. 6 (1), 49-53, (2011)

https://doi.org/10.2961/JLMN.2011.01.0011

Bobzin, K., Bagcivan, N., Gillner, A., Hartmann, C., Holtkamp, J., Michaeli, W., Klaiber, F., Schöngart, M., Theiß, S.:

Injection molding of products with functional surfaces by micro-structured, PVD coated injection molds

Prod. Eng. 5 (4), 415-422, (2011)

https://doi.org/10.1007/s11740-011-0319-9

Bobzin, K., Bagcivan, N., Theiß, S., Hartmann, C., Holtkamp, J., Gillner, A., Michaeli, W., Hopmann, C., Eilbracht, S., Schöngart, M., Scharf, M.:

Manufacturing of micro-structured parts for mass production purposes

Proc. of the Int. Symp. on Assembly and Manufacturing ISAM 2011, 25.5.-27.5. 2011, Tampere, Finland. (8 S.) (2011)

ISBN 978-1-61284-343-8 (digital)

https://doi.org/10.1109/ISAM.2011.5942365

Bobzin, K., Bagcivan, N., Ewering, M., Gillner, A., Beckemper, S., Hartmann, C., Theiß, S.:

Nano structured physical vapor deposited coatings by means of picosecond laser radiation

J. Nanosci. Nanotechnol. 11, (7 S.) (2011)

https://doi.org/10.1166/jnn.2011.3468

Bobzin, K., Bührig-Polaczek, A., Michaeli, W., Poprawe, R., Bagcivan, N., Beckemper, S., Eilbracht, S., Gillner, A., Hartmann, C., Holtkamp, J., Ivanov, T., Klaiber, F., Scharf, M., Schöngart, M., Theiß, S.:

Verkürzung von Prozessketten zur Herstellung von Bauteilen mit funktionalen Oberflächen mit Mikro-und Nanostrukturen

In: Brecher, C. (Hrsg.): Integrative Produktionstechnik für Hochlohnländer, 672-734, (2011)

https://doi.org/10.1007/978-3-642-20693-1_5

Hambach, N., Hartmann, C., Holtkamp, J., Gillner, A.:

Stability limits of laser drilled hole arrays on large areas.

ICALEO. 30. Int. Congr. on Applications of Lasers and Electro-Optics, October 23-27, 2011. M50, 895-899, (2011)

Holtkamp, J., Hartmann, C., Gillner, A., Beckemper, S., Dohrn, A., Eifel, S.:

Mikrostrukturieren mit Zukunft

Laser Technik J. 8 (2), 37-40, (2011)

https://doi.org/10.1002/latj.201190008

Ivanov, T., Bührig-Polaczek, A., Vroomen, U., Hartmann, C., Holtkamp, J., Gillner, A., Bobzin, K., Bagcivan, N., Theiss, S.:

Investment casting of surfaces with microholes and their possible applications

Light Metals 2011. Proc. of the technical sessions presented by the TMS Aluminum Committee at the TMS 2011 Annual Meeting & Exhibition. Warrendale, Pe.: TMS, Minerals, Metals & Materials Society. Chichester: Wiley, 705-709, (2011)

https://doi.org/10.1007/978-3-319-48160-9_123

Ivanov, T., Bührig-Polaczek, A., Vroomen, U., Hartmann, C., Holtkamp, J., Gillner, A., Bobzin, K., Bagcivan, N., Theiss, S.:

Replication of specifially microstructured surfaces in A356-alloy via lost wax investment casting

J. Micromech. Microeng. 21, 85026-85026, (2011)

https://doi.org/10.1088/0960-1317/21/8/085026

Michaeli, W., Schöngart, M., Klaiber, F., Beckemper, S.:

Production of superhydrophobic surfaces using a one-step variothermal injection moulding process

Micro Nanosystems 3, 222-225, (2011)

http://dx.doi.org/10.2174/1876402911103030222

Schaefer, M., Holtkamp, J., Gillner, A.:

Ablation of PEDOT/PSS with excimer lasers for micro structuring of organic electronic devices

Synth. Met. 161, 1051-1057, (2011)

https://doi.org/10.1016/j.synthmet.2011.03.014

Schaefer, M., Esser, A., Holtkamp, J., Gillner, A.:

Laser ablation of transparent conducting materials for organic electronics

Proc. of Large-Area, Organic and Polymer Electronics Convention 2011 (LOPE-C 11), June 2011, Frankfurt/M. Frankfurt/M.: Organics Electronics Association, 159-163, (2011)

Schulz-Ruhtenberg, M., Trusheim, D., Das, J., Krantz, S., Wieduwilt, J:

Influence of pulse duration in picosecond laser ablation of silicon nitride layers

Energy Proced. 8, 614-619, (2011)

https://doi.org/10.1016/j.egypro.2011.06.191

Schulz-Ruhtenberg, M., Häberle, A., Russell, A., Hernández, J. L., Krantz, S.:

Influence of the pulse width for visible pulsed laser doping for crystalline solar cells using phosphosilicate glass

J. Laser Micro/Nanoeng. 6 (1), 64-68, (2011)

https://doi.org/10.2961/jlmn.2011.01.0014

Sedao, X., Sarnet, T., Hernandez, J. L., Schulz-Ruhtenberg, M., Krantz, S.:

Edge isolation using ultra-short pulse laser materials with a top-hat beam profile

Adv. Mat. Res. 321, 234-239, (2011)

https://doi.org/10.4028/www.scientific.net/AMR.321.234

Trusheim, D., Schulz-Ruhtenberg, M., Baier, T., Krantz, S., Bauer, D., Das, J.:

Investigation of the influence of pulse duration in laser processes for solar cells

Phys. Proc.12, 278-285, (2011)

https://doi.org/10.1016/j.phpro.2011.03.134

Gillner, A.:

Laser micro-structuring

In: YI Qin: Micromanufacturing Engineering and Technology, Norwich, N.Y.: W. Andrew Publ. 2010. pp. 59-67.

ISBN 978-0-8155-1545-6

Huang, J., Wu, S., Beckemper, Gillner, A.

All-optical fabrications of ellipsoidal caps on azobenzene functional polymers

Opt. Lett. 35 (16), 2711-2713, (2010)

https://doi.org/10.1364/ol.35.002711

Schaefer, M., Jacobs, P., Bauer, D., Moll, D., Gillner, A.:

Investigation and development of a molding process for the production of micro-hairs

Int. J. Adv. Manuf. Technol. 51, 935-944, (2010)

https://doi.org/10.1007/s00170-010-2670-y

Schulz-Ruhtenberg, M., Haeberle, A., Russell, R., Hernández, J.L., Krantz, S.:

Quest for the ideal laser for an industrial laser doping process for crystalline solar cells

LPM 2010 - 11th International Symposium on Laser Precision Microfabrication, Stuttgart, (5 S.) (2010)

Schulz-Ruhtenberg, M., Hernandez, J. L., Prajapati, V., Bleidiessel, R., Morilla, C., Larmanda, Y., Vervisch, V., Sarnet, T., Olowinsky, A.:

Direct laser doping for high-efficiency solar cells

ICALEO 2009, 28th International Congress on Applications of Lasers & Electro-Optics, (4 S.) (2009)

https://doi.org/10.2351/1.5061472

Temmler, A., Willenborg, E., Pirch, N., Wissenbach, K.:

Structuring by remelting

Proc. of the 5th Int. WLT Conf. on Lasers in Manufacturing 2009, Munich, June 15th - 18th, 2009. Ed. by A. Ostendorf [u.a.] Stuttgart: AT-Fachverlag, pp. 403-407, (2009)

Poprawe, R., Gillner, A., Hoffmann, D., Gottmann, J., Wawers, W., Schulz, W.:

High speed high precision ablation from ms to fs

High-Power Laser Ablation 2008, 2008, Taos, New Mexico, United States.

Proceedings of SPIE Vol. 7005, High-Power Laser Ablation VII; 700502 (2008).

https://doi.org/10.1117/12.785225

Gillner, A.

Laser micro processing

Laser Technik J. 5, 27-30, (2008)

https://doi.org/10.1002/latj.200790202

Wortmann, D., Gottmann, J., Brandt, N., Horn-Solle, H.:

Micro- and nanostructures inside sapphire by fs-laser irradiation and selective etching

Opt. Expr. 16 (3), 1517-1522, (2008)

https://doi.org/10.1364/OE.16.001517

Fraunhofer Institute for Laser Technology ILT

Fraunhofer Institute for Laser Technology ILT